There are a variety of reasons to add essential oils to candle making. The most obvious reason is to add fragrance to the candle. However, essential oils can also be used to add beneficial properties to the candle. For example, adding lavender oil to a candle can help to promote relaxation and peace.

When adding essential oils to candles, it is important to use a carrier oil. Carrier oils help to dilute the essential oil and make it less potent. Some good carrier oils to use for candle making include jojoba oil, sweet almond oil, and grapeseed oil.

To add essential oils to a candle, start by measuring out the desired amount of oil. Then, add the oil to a small bowl. Next, microwave the oil for about 10 seconds. This will help to thin out the oil and make it easier to mix with the wax.

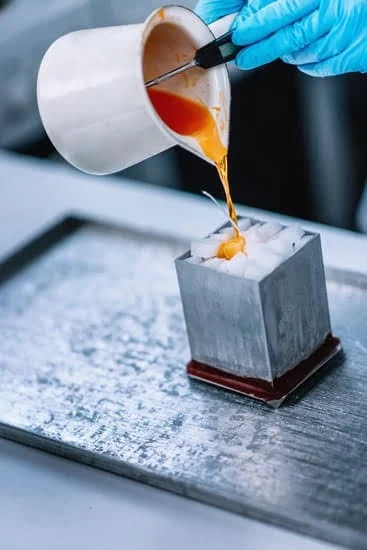

Then, add the oil to the wax. Stir the wax and oil together until the oil is fully mixed in. Be sure to use a thermometer to monitor the temperature of the wax. The wax should be heated to between 160 and 180 degrees Fahrenheit before adding the essential oil.

Once the wax is heated, add the essential oil. Stir the wax and oil together until the oil is fully mixed in. Be sure to use a thermometer to monitor the temperature of the wax. The wax should be heated to between 160 and 180 degrees Fahrenheit before adding the essential oil.

Then, pour the wax into the desired container. Allow the candle to cool completely before lighting it.

Right Wick Size When Making A Soy Candle

When making a soy candle, it is important to use the right size wick. If the wick is too small, the candle will not burn properly and will not produce enough heat to melt the wax. If the wick is too large, the candle will burn too quickly and will not produce a long-lasting flame.

The size of the wick depends on the diameter of the candle. For a candle that is 2 inches in diameter, you should use a wick that is 3/8 inch in diameter. For a candle that is 4 inches in diameter, you should use a wick that is 1/2 inch in diameter.

When choosing a wick, it is also important to consider the type of wax that is being used. For example, paraffin wax is a harder wax than soy wax. As a result, a wick that is appropriate for soy wax may be too large for paraffin wax.

If you are not sure which wick to use, it is best to start with a wick that is slightly smaller than the recommended size. You can always increase the size of the wick if necessary.

When To Add Fragrance Candle Making

Adding fragrance to candles is a personal preference. Some people like their candles to smell strongly of fragrance, while others prefer a light scent. In general, the more fragrance you add to a candle, the faster it will burn and the shorter the life of the candle will be.

There is no right or wrong time to add fragrance to candles. Some people add fragrance when they first make the candles, while others add it after the candles are already made. If you are adding fragrance to candles that are already made, you will need to use a hot wax melter to add the fragrance.

Adding fragrance to candles is a great way to customize your candles and make them smell the way you want them to smell. If you are making candles for yourself or for someone else, be sure to ask them what kind of scent they would like the candles to have.

Historical Candle Making Materials

The history of candle making is an interesting one, spanning many centuries and involving many different materials. The first candles were made from tallow, a type of animal fat, which was melted and then poured into a mold. The mold was typically made from a type of clay that was found near the candle maker’s home. Later on, beeswax became a popular material for candles, as it burns brighter and cleaner than tallow. Today, most candles are made from paraffin, a petroleum-based wax.

There are many different ways to make candles, but the basic process is always the same. The wax is melted and then poured into a mold. The mold is then placed in a cold environment, such as a fridge or freezer, to cool and harden. Once the wax has hardened, the candle can be removed from the mold.

The most important part of candle making is choosing the right wax. The type of wax you use will determine the type of candle you can make. For example, if you want to make a scented candle, you will need to use a type of wax that is compatible with fragrance oils.

There are many different types of waxes available, each with its own set of benefits and drawbacks. Here is a breakdown of the most common types of wax:

Tallow: Tallow is a type of animal fat that was the first material used to make candles. It is the cheapest and most readily available wax, but it is also the most toxic. Tallow candles produce soot and are a major contributor to indoor air pollution.

Beeswax: Beeswax is a natural wax made from the honeycomb of bees. It is the most expensive and environmentally friendly wax, but it also produces the cleanest and brightest flame. Beeswax candles are not compatible with fragrance oils.

Paraffin: Paraffin is a petroleum-based wax that is the most common type of wax used to make candles. It is cheap and easy to work with, but it produces a lot of soot. Paraffin candles are compatible with fragrance oils.

Peters Candle Factory Rents Equipment For Making Candles And Hires Students

To Make Candles

Peters Candle Factory rents equipment for making candles and hires students to make candles. The factory uses a variety of equipment, including candle making machines, molds, and wicks. The factory also uses different types of wax, including paraffin wax and beeswax.

The factory hires students to make candles because it is a great way for the students to learn about the manufacturing process. In addition, the factory can save money by hiring students, because the students are not paid as much as employees who have more experience.

The factory uses a variety of equipment, including candle making machines, molds, and wicks. The machines help to speed up the manufacturing process, and the molds help to create the desired shape of the candles. The wicks are important because they help to transfer the heat from the flame to the wax, which helps to melt the wax.

The factory uses different types of wax, including paraffin wax and beeswax. Paraffin wax is a type of wax that is made from petroleum. Beeswax is a type of wax that is made from bees. Both types of wax have different properties, and the factory uses both types of wax to create different types of candles.

The factory hires students to make candles because it is a great way for the students to learn about the manufacturing process. In addition, the factory can save money by hiring students, because the students are not paid as much as employees who have more experience.

The factory uses a variety of equipment, including candle making machines, molds, and wicks. The machines help to speed up the manufacturing process, and the molds help to create the desired shape of the candles. The wicks are important because they help to transfer the heat from the flame to the wax, which helps to melt the wax.

The factory uses different types of wax, including paraffin wax and beeswax. Paraffin wax is a type of wax that is made from petroleum. Beeswax is a type of wax that is made from bees. Both types of wax have different properties, and the factory uses both types of wax to create different types of candles.

The factory also uses different colors of wax, including red wax and green wax. The different colors of wax help to create different types of candles, and the different colors of wax also create a festive look.

The factory hires students to make candles because it is a great way for the students to learn about the manufacturing process. In addition, the factory can save money by hiring students, because the students are not paid as much as employees who have more experience.

The factory uses a variety of equipment, including candle making machines, molds, and wicks. The machines help to speed up the manufacturing process, and the molds help to create the desired shape of the candles. The wicks are important because they help to transfer the heat from the flame to the wax, which helps to melt the wax.

The factory uses different types of wax, including paraffin wax and beeswax. Paraffin wax is a type of wax that is made from petroleum. Beeswax is a type of wax that is made from bees. Both types of wax have different properties, and the factory uses both types of wax to create different types of candles.

The factory also uses different colors of wax, including red wax and green wax. The different colors of wax help to create different types of candles, and the different colors of wax also create a festive look.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.