Candle making is a popular hobby and creative outlet for many individuals. When it comes to choosing the right materials for candle making, two common options are aluminum and stainless steel containers. Both materials offer distinct benefits and features that cater to different preferences and needs.

Aluminum containers are lightweight, durable, and easily recyclable, making them a popular choice among candle makers. They conduct heat efficiently, resulting in more even burning of the candle wax. Additionally, aluminum containers provide a modern and sleek aesthetic that can enhance the overall presentation of your candles.

On the other hand, stainless steel containers are known for their durability and resistance to corrosion, making them ideal for long-term use in candle making. Stainless steel also offers a higher level of insulation compared to aluminum, which can help maintain consistent temperatures while the candle burns. This material is perfect for those looking for a more traditional and robust option for their candle making endeavors.

In this article, we will explore the benefits of using both aluminum and stainless steel containers for candle making. We will also compare the two materials to help you determine the best choice for your specific needs. Whether you prefer the lightweight versatility of aluminum or the durability of stainless steel, we will provide tips on how to choose the right material for your candle making projects.

Benefits of Using Aluminum for Candle Making

Aluminum containers are a popular choice among candle makers for several reasons. Firstly, aluminum is a lightweight and durable material, making it easy to handle and transport during the candle-making process. The lightweight nature of aluminum also makes it convenient for pouring wax and creating a variety of candle shapes and sizes without added strain.

Additionally, aluminum is known for its excellent heat conductivity, which can help ensure even and efficient distribution of heat while melting wax. This property is crucial in candle making as it helps prevent hotspots that can lead to uneven melting or burning of the candle. The consistent heat distribution provided by aluminum containers also aids in achieving a smooth finish and reducing the risk of imperfections in the final product.

In terms of cost-effectiveness, aluminum containers are relatively affordable compared to other materials like stainless steel. This makes them an attractive option for beginner candle makers or those looking to produce candles on a larger scale without breaking the bank. Furthermore, aluminum containers are easy to clean and maintain, requiring minimal effort to keep them in good condition for repeated use in candle making projects.

Benefits of Using Stainless Steel for Candle Making

Stainless steel is a popular choice for candle making due to its unique properties that make it ideal for this craft. One of the main benefits of using stainless steel containers for candle making is their durability. Stainless steel is known for its strength and resistance to corrosion, making it a long-lasting option for candle makers. This means that once you invest in stainless steel containers, you can use them repeatedly without worrying about wear and tear.

Another advantage of using stainless steel for candle making is its ability to retain heat. Stainless steel containers have excellent heat conductivity, allowing candles to melt evenly and consistently during the pouring process. This feature is crucial in achieving high-quality candles with a smooth finish. Additionally, stainless steel containers are easy to clean and maintain, making them a convenient option for candle makers.

Corrosion Resistance

Stainless steel containers are also highly resistant to corrosion, which is crucial when working with materials like wax and fragrance oils that can be harsh on certain metals. This means that stainless steel containers will not react with the candle ingredients, ensuring that your candles remain safe and free from any contaminants. The corrosion resistance of stainless steel makes it a reliable option for candle makers who prioritize the quality and safety of their products.

Versatility

Furthermore, stainless steel containers come in various sizes and shapes, providing candle makers with versatility in their candle-making projects. Whether you need small tins for travel candles or larger vessels for decorative candles, stainless steel containers offer a range of options to suit different needs. This flexibility allows candle makers to explore different designs and styles, enhancing their creativity in crafting unique candles.

Comparison of Aluminum and Stainless Steel in Candle Making

When it comes to choosing the right material for your candle making supplies, considering whether to use aluminum or stainless steel can make a significant difference in the quality and outcome of your candles. Both materials have their own unique properties that can impact the candle making process and the final product.

Below is a comparison between aluminum and stainless steel in candle making:

- Heat Conductivity: Aluminum is known for its excellent heat conductivity, which allows for even heating and faster melting of wax. This can help save time during the candle making process and create a more consistent end product. On the other hand, stainless steel has lower heat conductivity compared to aluminum, which may result in slower melting and a more gradual cooling process.

- Durability: Stainless steel is generally more durable than aluminum, as it is more resistant to scratches, dents, and corrosion. This makes stainless steel containers ideal for long-term use and repeated candle making sessions. However, aluminum containers are lightweight and easier to handle, which can be beneficial for those who prefer portability and ease of maneuvering while working on their candles.

- Cleaning and Maintenance: While both aluminum and stainless steel are relatively easy to clean, stainless steel has an edge when it comes to resistance against staining and tarnishing. Aluminum containers may require more frequent cleaning to maintain their appearance, especially if they come into contact with certain types of candle dyes or fragrances that can cause discoloration over time.

Consider these factors when deciding between aluminum or stainless steel for your candle making supplies to ensure that you choose the material that best suits your needs and preferences. Ultimately, both materials have their advantages in the candle making process, so it’s important to weigh these considerations based on your specific requirements before making a decision.

Tips for Choosing the Right Material for Candle Making

When it comes to choosing the right material for candle making, considerations like heat conductivity, durability, and aesthetic appeal play a significant role. Both aluminum and stainless steel are popular choices for candle making containers due to their unique properties.

Aluminum is lightweight, affordable, and offers excellent heat conduction, making it ideal for evenly distributed heat during the candle-making process. Additionally, aluminum containers are available in various shapes and sizes, providing versatility for different types of candles. The malleability of aluminum also allows for creative designs to be molded easily.

Stainless steel, on the other hand, is known for its durability and resistance to corrosion, making it a long-lasting option for candle making supplies. Its sleek appearance adds a touch of elegance to your candle creations while ensuring that the container remains resilient over time. Stainless steel containers are easy to clean and maintain, perfect for reuse in future candle-making projects.

| Material | Properties |

|---|---|

| Aluminum | Lightweight, affordable, excellent heat conduction |

| Stainless Steel | Durable, corrosion-resistant, sleek appearance |

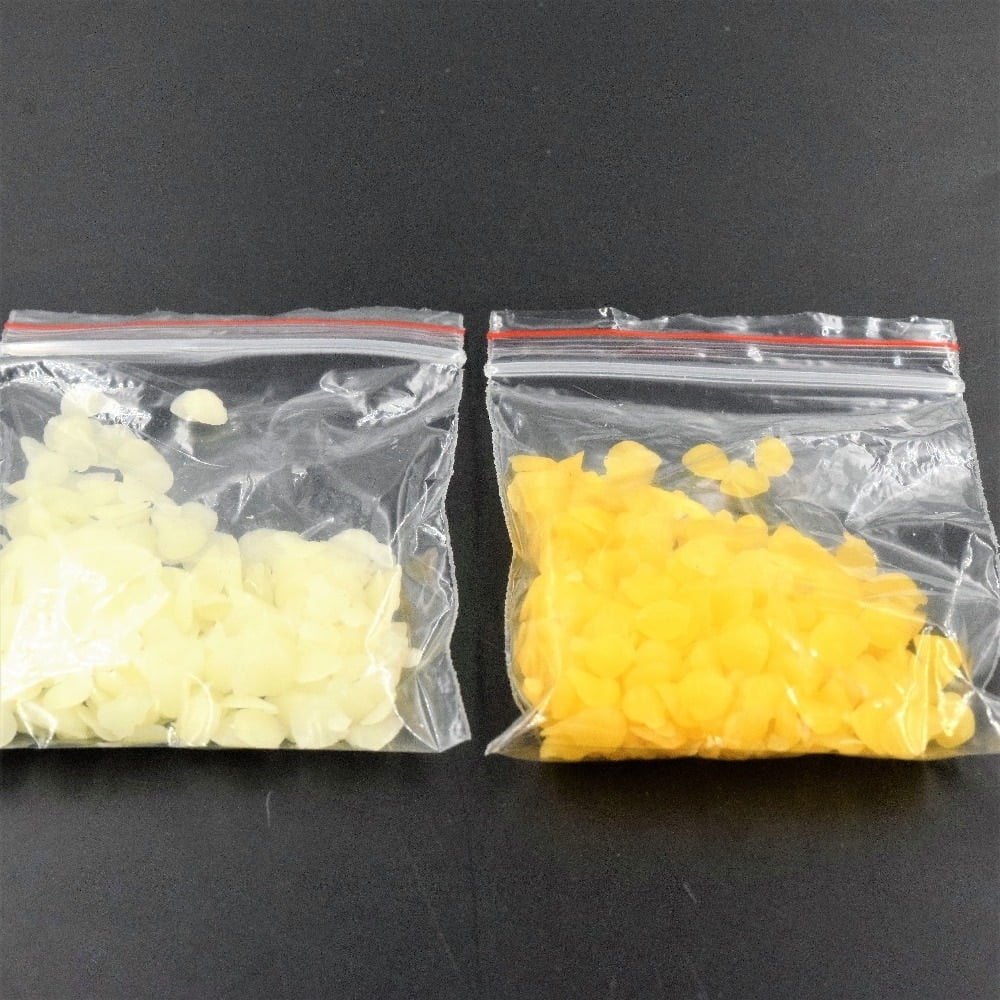

Types of Aluminum and Stainless Steel Containers for Candle Making

When it comes to candle making, the type of container you choose can significantly impact the overall quality of your candles. Aluminum and stainless steel containers are popular choices due to their durability, heat resistance, and sleek appearance.

Aluminum containers are lightweight and offer excellent heat conduction, which helps in even burning of candles. They are also rust-resistant, making them a long-lasting option for candle makers. Additionally, aluminum containers come in various shapes and sizes, allowing for creativity in candle designs.

On the other hand, stainless steel containers are sturdy and offer superior resistance to corrosion. This makes them a great choice for candle makers who want long-lasting containers that maintain their aesthetic appeal over time. Stainless steel containers also come in different finishes like matte or polished, providing options for different design preferences.

One important factor to consider when choosing between aluminum and stainless steel containers for candle making is the reusability aspect. While both materials are durable, stainless steel typically has a longer lifespan than aluminum. For candle makers looking to invest in reusable containers that will withstand multiple uses, stainless steel might be the better choice in the long run.

| Aluminum Containers | Stainless Steel Containers |

|---|---|

| Lightweight | Sturdy |

| Excellent heat conduction | Superior resistance to corrosion |

| Rust-resistant | Different finishes available (matte or polished) |

Maintenance and Care for Aluminum and Stainless Steel Candle Making Supplies

Aluminum and stainless steel are popular choices for candle making supplies due to their durability and heat-resistant properties. Proper maintenance and care of these materials are essential to ensure the longevity of your candle-making tools. Here are some tips for maintaining and caring for aluminum and stainless steel candle making supplies:

- Regular Cleaning: To keep your aluminum and stainless steel containers clean, it is important to wash them after each use with mild soap and water. Avoid using abrasive cleaners or scrubbing pads that can scratch the surface.

- Drying: After washing, make sure to dry your aluminum and stainless steel candle making supplies thoroughly to prevent water spots or rust from forming. Towel dry or air dry completely before storing.

- Storing: Store your aluminum and stainless steel candle making supplies in a cool, dry place away from direct sunlight or heat sources. This will help prevent any discoloration or warping of the materials over time.

Proper maintenance of your aluminum or stainless steel candle making supplies not only ensures their longevity but also helps maintain the quality of your candles. By following these simple care tips, you can continue to create beautiful candles with ease.

Additionally, if you notice any signs of wear or damage on your aluminum or stainless steel candle-making tools, such as dents, scratches, or corrosion, it may be time to replace them. Investing in high-quality materials and properly caring for them will ultimately save you time and money in the long run.

Remember that regular maintenance and care are key factors in extending the life of your aluminum or stainless steel candle making supplies. By taking the time to properly clean, dry, store, and inspect your tools, you can enjoy many successful candle making sessions without worrying about the condition of your materials.

Conclusion

In conclusion, when it comes to choosing between aluminum or stainless steel for candle making, both materials offer unique benefits and advantages. Aluminum containers are lightweight, affordable, and offer excellent heat conduction, making them ideal for efficient and even burning of candles. On the other hand, stainless steel containers are durable, long-lasting, and resistant to corrosion, ensuring your candle making supplies stay in good condition for a long time.

Ultimately, the choice between aluminum or stainless steel for candle making will depend on your specific needs and preferences. If you prioritize cost-effectiveness and thermal conductivity, aluminum may be the perfect choice for you. Alternatively, if durability and resistance to corrosion are essential factors for you, stainless steel might be the better option.

Regardless of your decision, both aluminum and stainless steel containers can enhance your candle making experience by providing a reliable and sturdy vessel for your creations. Remember to consider factors such as budget, maintenance requirements, and aesthetic preferences when selecting the right material for your candle making needs. Whichever material you choose, rest assured that with proper care and maintenance, both aluminum and stainless steel containers can serve you well in your candle making endeavors.

Frequently Asked Questions

Can You Make Candles in Aluminum?

Yes, you can make candles in aluminum containers. Aluminum is a popular choice for candle making due to its heat-conducting properties and ability to withstand high temperatures. Just be sure to use caution when handling hot wax to avoid burns.

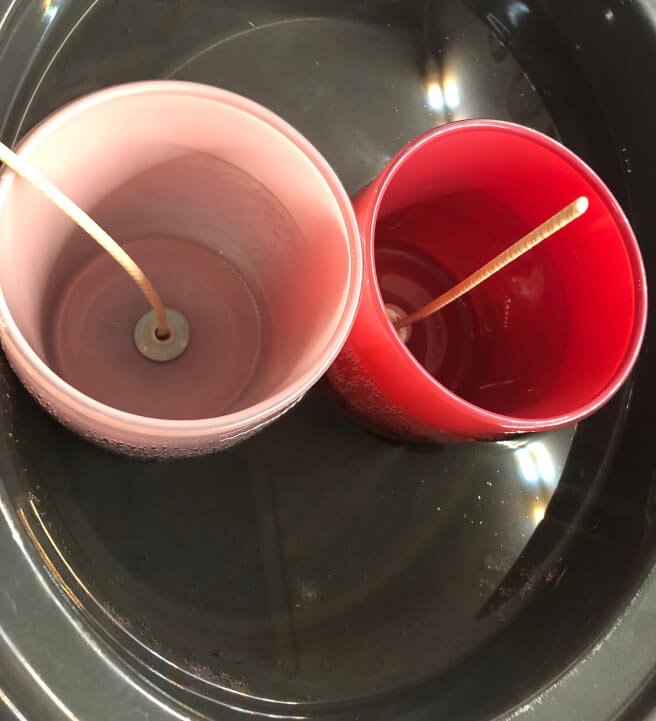

What Pan to Use for Candle Making?

When it comes to choosing a pan for candle making, it’s best to use a double boiler system with a stainless steel or glass container as the inner pot. This will help prevent direct contact between the flame and the wax, reducing the risk of fire. Using a dedicated candle-making pitcher is also recommended for convenience and safety.

Can You Melt Wax in Stainless Steel?

While stainless steel is generally safe for melting wax, it’s important to exercise caution and avoid overheating the material as it can degrade over time. Use low to medium heat settings when melting wax in stainless steel containers and monitor the temperature closely to prevent damage.

Additionally, make sure the stainless steel container is clean and free from any residues before melting wax in it.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.