Automatic Candle Making Machine Video

There are different types of machines used for candle making. One of the most popular machines is the automatic candle making machine. The automatic candle making machine is used to produce candles of different sizes, shapes and colors. The machine consists of a number of parts that work together to produce candles. The first part of the machine is the hopper. The hopper is used to hold the wax that is used to make the candles. The wax is melted and then poured into the molds to create the candles. The molds are then placed in the oven to harden. Once the candles are hardened, they are removed from the molds and placed in the cooling area. The cooling area is used to cool the candles before they are packaged and shipped to the customer.

Candle Making Machine Suppliers In Pune

Looking for a candle making machine supplier in Pune? Look no further than the experts at Super Candles. We offer a wide range of candle making machines that are perfect for any business, from small to large.

Our machines are easy to use and are perfect for producing high-quality candles quickly and efficiently. We also offer a wide range of customization options to ensure that you get the perfect machine for your business.

Contact us today to learn more about our candle making machines and how we can help you get started in the candle making business.

China Candle Making Machine

Candle making machines are an important part of the candle making process. They are used to create the candles that we all know and love. There are many different types of candle making machines, and each one has its own unique set of features.

One of the most common types of candle making machines is the moulding machine. This machine is used to create the basic shape of the candle. It is also used to add the wick to the candle. The moulding machine is a very important part of the candle making process, and it is responsible for creating the majority of the candles that we use.

Another common type of candle making machine is the pouring machine. This machine is used to add the wax to the candle. It is also used to add the color and the scent to the candle. The pouring machine is an important part of the candle making process, and it is responsible for adding the finishing touches to the candle.

Candle making machines are an important part of the candle making process. They are used to create the candles that we all know and love. There are many different types of candle making machines, and each one has its own unique set of features.

One of the most common types of candle making machines is the moulding machine. This machine is used to create the basic shape of the candle. It is also used to add the wick to the candle. The moulding machine is a very important part of the candle making process, and it is responsible for creating the majority of the candles that we use.

Another common type of candle making machine is the pouring machine. This machine is used to add the wax to the candle. It is also used to add the color and the scent to the candle. The pouring machine is an important part of the candle making process, and it is responsible for adding the finishing touches to the candle.

Automatic Candle Making Machine Factories

The beauty industry is constantly expanding, with new products and services being developed all the time. This is especially true for candles, which are becoming more and more popular every day. However, making candles can be a time consuming and difficult process. That’s why more and more people are turning to automatic candle making machine factories to get their candles made quickly and easily.

An automatic candle making machine factory is a factory that specializes in making candles using machines. These factories are able to produce large quantities of candles quickly and easily, and they can do so at a fraction of the cost of traditional candle making methods.

There are a number of different types of automatic candle making machine factories, each of which has its own unique set of advantages and disadvantages. The most common types of automatic candle making machine factories are the following:

1. Pressing factories: Pressing factories are the most common type of automatic candle making machine factory. These factories use machines to press the wax into the desired shape and size. This is the most efficient and cost effective way to make candles, and it is the type of factory that is most commonly used to make large quantities of candles.

2. Injection factories: Injection factories are similar to pressing factories, but they use machines to inject the wax into a mold. This type of factory is less common than pressing factories, but it is still used to make a significant amount of candles.

3. Blow molding factories: Blow molding factories are the most expensive type of automatic candle making machine factory, but they are also the most efficient. These factories use machines to blow the wax into a mold, which results in a high quality candle.

If you are looking for a high quality, affordable candle, then you should consider using an automatic candle making machine factory. These factories are able to produce large quantities of candles quickly and easily, and they can do so at a fraction of the cost of traditional candle making methods.

Old Fashioned Candle Making Machine

As the name suggests, an old fashioned candle making machine is one that is used to produce candles in a more traditional way. This type of machine has been used for centuries, and is still popular among many candlemakers today.

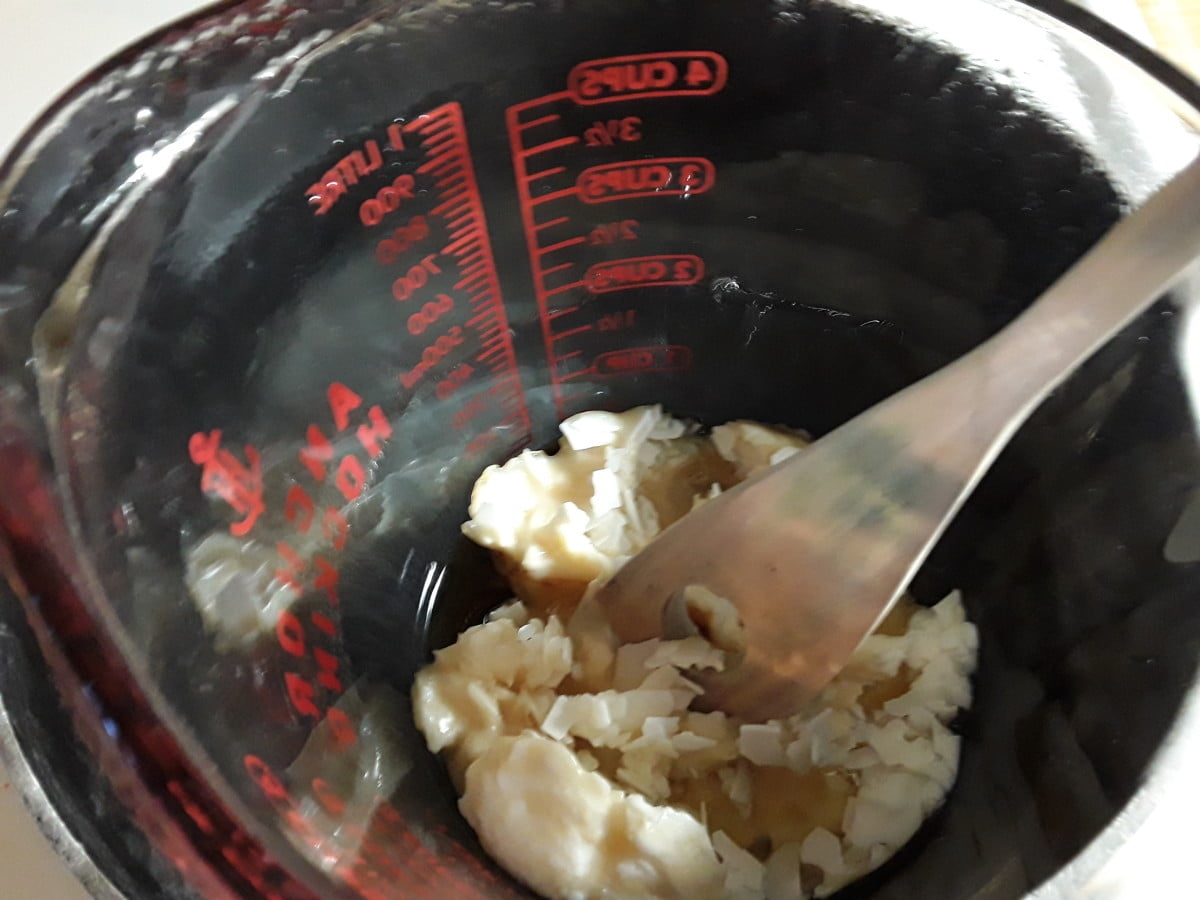

An old fashioned candle making machine typically consists of a large vat or pot in which the wax is melted, and a number of different-sized molds into which the wax is poured. The molds can be simple or intricate, depending on the desired final product.

Once the wax has been poured into the molds, it is left to cool and harden. Once it has hardened, the candles can be removed from the molds and used as desired.

There are a number of different types of old fashioned candle making machines available on the market, each with its own set of advantages and disadvantages. It is important to do your research before purchasing one of these machines, to make sure you get the one that is best suited to your needs.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.