Introduction

Candle making is the process of transforming wax, fragrance, and color into decorative and functional objects that add beauty and ambiance to any event or celebration. Through the art of candle making, crafters can create unique pieces to commemorate special moments and make occasions more meaningful. By selecting different materials to transform plain wax into aesthetically pleasing works of art, it’s possible to show off your creativity while providing guests with something beautiful to take home as a memento.

The first step in candle making is gathering the necessary supplies. Depending on the type of project being undertaken (tapers, votives, pillars etc.), you may need beeswax, paraffin wax or soy wax, wicks, sparkles and other embellishments for decorating your candles. Essential oil scent blends featuring spices such as ginger and cinnamon will bring a festive feel to any occasion. Next choose one or two colors for coloring each section of the candle individually – either freehand brush painting or various pouring techniques can be used for this stage. Finally pour hot melted wax”or scoop pre-made melts”into molds or containers before allowing the material to harden overnight at room temperature before adding an extra layer of wax should this be necessary.

It’s easy to customize candles to suit any special occasion by varying scent combinations and colors according to individual preference. To give tapers a pop of texture, dip them in glitter or drizzle them with metal flakes mixed with wax using a syringe; you could also add LED lights for interest when entertaining after dark. Pillar candles representing birthdays or religious festivals may benefit from having circular shapes pierced onto their surfaces for added visual impact; visually arresting votive designs could combine swirls of white pigment with glittering shapes atop blended shades like pink champagne or light blue too.

Exploring Different Types of Wax for Candle Making

When crafting handmade candles, the type of wax chosen has a profound influence on the candle. There are many types of wax available for use in candle making and each has unique properties that may affect performance, longevity, scent throw, or heat resistance. Making an informed choice about which wax to use will ensure the best possible outcome for your candle.

Paraffin wax is derived from petroleum and is considered a standard option for pouring containers because it holds colorant and fragrance well. Although this type of wax comes in a variety of melting points, it is known to create smoke and soot when burning and should not be used near fire sources that produce weak flames including tealights. In addition, paraffin can be difficult to clean up if spilled as it hardens quickly when cool.

Soy wax is an eco-friendly alternative as it is made from vegetable oils which makes it biodegradable. This type of wax has a much smoother burn than paraffin and creates almost no soot or smoke, aiding in lower-profile creations such as votive candles. After curing with proper ventilation, soy candles tend to hold both their shape and fragrance very well within their containers with minimal shrinking.

Beeswax is another popular option for container candles as it produces very little smoke due to its natural low melt-point properties. Beeswax also has a naturally pleasant smell which compliments additional fragrances easily without overpowering them. However, because this type of wax has an increased melting temperature when compared to other varieties, there is a greater risk of cracking upon cooling due to sudden temperature changes during the cooling process – so thorough preparation before pouring into the containers will assist with the stability once hardened.

Comprehensive Guide to the Candle Making Process in Telugu

The process of making candles can be both enjoyable and rewarding, whether you are making a few candles as a hobby or producing larger quantities for commercial sale. Making attractive, high-quality candles doesn’t have to be overly complicated either.

To get started with the candle-making process in Telugu (and throughout India), below is an overview of the general steps and materials you need, along with some helpful pointers.

Step 1: Gather all your candle-making supplies: You will need various pieces of equipment based on the type of candle you plan to make, but all include wax, wick material and containers or molds, as well as other items such as safety glasses, gloves, thermometers and fragrances.

Step 2: Set up your workspace for candle making: Make sure that this is a safe area away from any children or animals. A workbench in a shed which is away from direct heat sources would work best.

Step 3: Prepare your wax for melting: This involves measuring out your wax into chunks ” if it has harden considerably by storage then cut it into smaller pieces – and placing them in the container you will be using to melt them down e.g a double boiler or an aluminium pot over an electric hotplate.

Step 4: Melt the Wax on low temperature setting carefully either higher temperatures can cause burning aromas and smoke releases so watch it and stir occasionally : At this stage you may find it useful to add colourants (dyes) and fragrance oils if desired for particular types of candles noted earlier let ensure prevents clumping

Step 5: Pouring melted wax into container molds/holder vessels: Using proper cloth gloves pour heated wax gently into container/moulds fill up half way first and hold wick in middle before filling out rest ensures evenly dispersal of hot liquid wax avoid spilling takes some practice! Move mold around slightly after each pour my stirred mixture gets evenly spreaded outwards . Allow candles cool down few hours before removing from forms/holders

Step 6 Add decorations if desired such as sticks beads glitter stars etc. : You can adorn your hand made candles however you choose depending on what kind they are like tapers votives use decorations like label strips ribbons etc remember always keep safety first when working with flammable substances ! Finally seal finished products with specialised protective coating solution help maintain their properties longer.

With these basic steps outlined above and the right materials on hand, anyone can confidently start making their own unique creations with ease!

Outlining the Chemistry of Melting Wax and Color Blending

Candle making is an art that combines the science of melting wax and the technique of color blending. Candle making begins with melting the wax, which requires the user to determine what type of wax should be used based on the desired outcome. The type of wax can range from natural beeswax, paraffin, and soy wax; each possessing different properties such as hardness, heat resistance, fragrancy, and production costs.

Once the user has identified the appropriate type of wax, it must then be melted. This is usually done using a double boiler or a double pot system. It is important to use caution when heating wax since it happens at extremely high temperatures that are potential safety hazards if not handled properly. Once melted, other additives such as candle dye may be added to adjust the color of the candle if desired. This component also involves determining a scale for measuring out desired parts as different quantities can produce vastly different hues to your candles.

Once all additives have been added, a wick must be placed in order for our candle creation to display correctly and evenly while burning away. Wicks provide support and stability while guiding the flame in one direction; there is a variety of materials available when selecting your wick material such as wood-cored cotton and flat braided cored wicks which each have their own unique benefits and drawbacks depending on what type of effect you are looking for during burning time.

Finally these components combine together to form an entirely new product; molten hot wax shaped by artistic creativity into something beautiful! After allowing ample cooling time afterwards this final product can finally be displayed proudly among family or friends as living testimony to ones creative capabilities!

How to Design Unique Candles for Personalization

Candle making is not just a fun and creative craft, but it’s a great way to make personalized gifts that your friends and family will cherish. By using a variety of materials such as wax, scented oil, color dye, glitter, beads and more along with some basic materials like wicks and moulds, you can design unique candles for personalization. Let us follow the step by step process below:

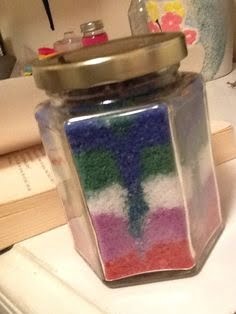

1. Choose Your Colors and Fragrances: Pick out a variety of fragrances and colors to get started with creating your own personalized candle. Some combinations may include essential oils such as lavender or bergamot combined with soft pastel hues or vibrant jewel tones in blues, greens and purples for an inviting candle display.

2. Gather Materials: Purchase pre-made wicks from your local craft store or use dyes if you prefer to color your wax yourself. Select moulds for the shape you desire; buy tins or jars if you plan on producing multiple candles in different sizes at once.

3. Heat Wax Over Boiling Water: Melt your wax over boiling water in a double boiler set up on the stovetop until all lumps have been integrated into liquid form then add desired fragrances and dye according to directions given on the containers they are purchased in.

4. Pour Mixture Into Moulds: Cut wick strands 10-12 inches long towards one another at right angles when forming an ‘X’ shape before resting them onto the bottom of each mould before pouring in melted mixture slowly and evenly whilst ensuring your pouring does not disrupt its surface tension so it remains smooth after cooling down completely before removing from its mould.

5. Personalize & Display Your Candle Gifts: Once cooled down decorate each individual candle with glitter or any other desired material that adds texture such as sequins or buttons! And finally offer these stunning creations as sentimental homemade gift ideas during special occasions like birthdays, anniversaries or housewarmings ” their recipients will truly appreciate the effort put into crafting them!

A Troubleshooting Guide to Common Candle Making Problems

When making candles, the process can be tricky. You may find yourself running into the same problems over and over again. Having a troubleshooting guide handy can save time and frustration. Below is a helpful guide to common candle-making problems with solutions.

• Burning unevenly: If your candle burns unevenly, you might not have allowed it to burn long enough for the wax pool to reach the edges of the container or jar. Try letting your candle slowly melt until it covers the edge.

• Tunneling: This means that your candles are burning down in the middle, leaving a lot of unmelted wax around the edges of the container or jar. To prevent this from happening, allow your candles enough time to initially burn until they form a full wax pool throughout their whole surface area on subsequent burns.

• Black smoke: If your candles emit a lot of black smoke, then it’s possible that there’s too much fragrance oil being added during production. Make sure that you’re following recommended guidelines for maximum percentage additions when adding fragrances or dyes to your candle mix, otherwise you risk having smoky soot emitted from them.

• Sagging Container Wax: After several burns and cooling cycles, some containers can start to warp if too large of a wick has been used with them (especially ones made out of thin plastic). That’s because heat from successive burns naturally weakens containers overtime and causes sinking or sagging around wicks due to low-grade containers becoming overwhelmed by larger wicks than what they were designed for. To increase longevity of these type of containers, either use an appropriate size wick for its size or opt for using glass jars instead which are much more heat resistant and durable against prolonged exposure over time.

Tips for Making Professional Quality Candles in Telugu

1. Select high-quality wax: The type of wax you choose is crucial for making professional quality candles. In Telugu, we recommend using a low melting point wax variety such as beeswax or paraffin, as they hold their shape better and have a more consistent burn time.

2. Measure the right amount of wax: To ensure your wicks are properly set, it’s important to measure the right amount of wax each time you craft a candle. We suggest that you use a digital cooking scale when measuring out your wax amounts ” this will not only help cut down on mess but also give you a precise and consistent measurement every time.

3. Use high-quality scents/additives: Another essential step in making professional quality candles is ensuring that you use premium grade scent oils for your candles. This will allow you to control the strength of the scent, resulting in a pleasant smelling result with every candle.

4. Find the best wicks: Wicks play an important role in candle making, so it’s vital that you do your research and select one which is suitable for your style of candle. Look out for cotton wicks, zinc cores, and wick off-sets – this will help achieve even burning during its production as well as when it’s used by consumers at home!

5. Keep molds clean & dry: It’s recommended that all molds should be kept clean before pouring in order to avoid trapped air particles which can lead to cracks or divots on the surface once cooled. Store them away from moisture and direct sunlight if possible – this will yield the best results!

6. Monitor temperature throughout process: Controlling heat is key when creating a professional product ” make sure to monitor temperatures both during melting process and also when cooling down after pouring into molds to prevent any imperfections from forming on your finished product!

Concluding Thoughts

By researching the process of candle making in Telugu, I have learnt that it is a relatively straightforward process. The basic steps are to mix together wax, scent and colourant before pouring it into a mould or container and letting it set. The process can be decorated to produce more creative candles. Furthermore, scent should be chosen carefully as each type of wax has its own properties which affect how the smell will develop. Knowing all this makes it easier to determine which kind of wax and scents would work best for my desired outcome. Lastly, by learning the candle making process in Telugu, I have gained an insight into how wicks, colourants and ornamental effects like swirls are added to create unique pieces of art.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.