Introduction

Candle making is an age-old craft that has been practiced since ancient times. Not only do candles provide light and warmth, they can also be used in a variety of ways such as meditation, ceremony and celebration. Candle making materials can vary greatly in price; however, there are some basics that can help you on your candlemaking journey. Candles require wax, wicks, dyes and fragrances all of which are important to consider when purchasing the appropriate supplies to make your desired candles.

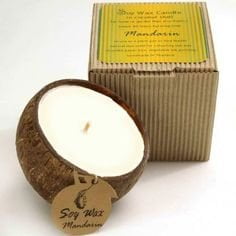

Wax is often the most expensive ingredient when making candles and may include soy wax, beeswax or paraffin wax. Soy wax is an all natural wax derived from soybeans and is biodegradable which makes it an environmentally friendly option for those concerned about their carbon footprints. Beeswax has a natural sweet aroma to it but does require extra care when being melted down due to its unique properties when subject to too much heat or moisture. Paraffin wax, on the other hand, is derived from petroleum products and very economic choice; however it may pose environmental issues if not disposed of in the proper matter according to local laws.

Once the wax has been chosen the next step is to select wicks suitable for the type of wax being used in order for them not to melt or burn too quickly. Wicks generally range in price depending on the length and size needed but also due to any flame resistance/retardant additives they may have as well as whether they are pre-tabbed (already connected to a sufficient base).

Lastly other options include fragrance oils, dyes and molds which although not essential can supplement your candle’s overall look and ambience if desired. Fragrance oils come in many different scents ranging from food based scents (vanilla bean) or floral scents (rose), both usually at a low price point. Dyes are also another option with a range of vibrant colors available enabling you add extra finesse to your candle creations; however these come at a price per ounce so consider this factor carefully prior to purchase. Lastly molds come in many shapes sizesand textures allowing you create any shape you desire -considering you have obtained them (you could choose between buying pre-fabricated molds or even collecting empty food containers).

In conclusion candle making raw materials prices will vary significantly between each type -while certain items maybe more sustainable others may be better suited economically; however assessing all factors prior creating allows you get started without any major setbacks!

Types of Materials

Wicks: Wicks are a critical component of any candle-making process. The main role of the wick is to draw liquid fuel (melted wax) up into the flame, allowing it to burn gently and without smoke. Beeswax, cotton, or linen wicks are all popular materials used in candle-making. Beeswax has a longer burn time but can be difficult to work with and some prefer to use cotton or linen for their projects. Cotton and linen both have good absorption rates and flexibilities but have shorter burn times when compared to beeswax.

Wax: Setting the foundation of most candles, wax serves as the liquid fuel around which wicks are usually placed. The most popular forms of waxes used in making candles include soy wax, beeswax, paraffin, coconut wax, palm wax, and more. Each type of wax offers its own benefits such as soy wax being 100% natural, paraffin burning cleanly and evenly with brilliant colors when dyed and scented properly, beeswax producing a bright white color and a pleasant aroma when melted down with essential oils or fragrances added. Alternatives include vegetable-based oils such as almond oil and shea butter that can be used in place of paraffin or other petroleum based candle fuels.

Dyes: Candle makers may choose to add dye or pigment to provide color to their creations by melting down certain types of dyes directly into the melted wax before it cools down (pouring/dipping). Some common dyes used in this way are tea leaves, natural pigments from fruit shells & cocoa powder for beautiful oranges & browns respectively – these can all be found in health food stores; lampblack for deep blacks; alkanet from root extract for rich mauve purples; anatto seed from Akar Farma for brilliant yellows & reds; powdered spices such as turmeric & paprika; activated charcoal & chlorophyll powder for cool looking greens; brick-red iron oxide minerals including hematite & ochre oxides are also popularly used dyes amongst professional artisanal hand candle makers who wish to craft unique handmade items using natural ingredients.

Scents: Adding scent is an important step in most candle-making processes because it helps create an environment conducive to relaxation or aromatherapy purposes — depending on what scent you use! Aromachemicals such as terpenoids offers long lasting fragrances while essential oils typically provide more natural scents that spread well across a room’s air space. Other alternatives include phthalate free fragrance oil that feature synthetic fragrances — many synthetics offer better smell durability than essential oils yet petrochemical free room fresheners may be carotene based alternate woodwick replacements that emit no smoke at all nor produce toxins when heated like some synthetic fragrances do.

Raw Material Sources

Domestic Raw Materials: There are several sources for domestic raw materials for candle making. The most common include beeswax (from local beekeepers), soy wax, and paraffin. Beeswax has a pleasant aroma and gives off a warm glow when lit. Soy wax is made from the oils of pressed soybeans and it is more sustainable than other waxes. Paraffin candles are more affordable and do not require as much maintenance to keep alive as other types of candles.

Pros & Cons for Each:

Beeswax Pros: Natural, great scent, long burning time.

Cons: Can be expensive, not readily available in every region.

Soy Wax Pros: Sustainable, renewable resource that produces an even burn, environmentally friendly.

Cons: Low melting point can cause uneven burning and shortening of candle’s life-span in warmer temperatures.

Paraffin Pros: Economically priced, widely available.

Cons: Non-renewable source releases toxins into the air when burned; if not properly fragranced can produce an unpleasant smell while burning.

International Raw Materials: There are also many international sources for candle making raw materials such as jasmine flower petals from India, beeswax from Canada, palm oil from Africa, etc. These foreign suppliers offer unique ingredients at good prices but may take longer to receive due to shipment distances and customs regulations/tariffs for importing goods into the US market

Pros & Cons for Each:

Jasmine Flower Petals Pros: Classy scent that stays for longer periods of time without any additives needed; grown cleanly without the use of any pesticides or fertilizers; comparatively cheaper than more luxurious ingredients like genuine beeswax and paraffin waxes from international sources

Cons: Harvesting flowers may be labor intensive with few farmers involved in this type of work; seasonally sourced product with varying degrees in availability depending on climate conditions

Beeswax Pros: Gives off warm glow when lit alongside producing a pleasant aroma; sustainably sourced material

Cons: Insecticides used during harvesting may be found in minor amounts within bee products; pricey resource especially when purchased internationally

Palm Oil Pros: Widely available diversity enables water resistant characteristics ideal for hot climates; strong combustion powers create brighter lighting effects lasting longer than traditional materials such as pure paraffin

Cons : Unsustainable practice if harvested carelessly removing vegetation leading to deforestation-like consequences; large import taxes attached when bringing merchandise international

Factors to Consider When Pricing Materials

It is important to take into account the cost factors when pricing materials for candle making. These can include the brand and source of the materials, as well as production costs associated with the raw materials. Quality matters, so make sure you carefully analyze the raw material options to pick out the most reliable ones with a long shelf life. Also, consider any environmental and ethical implications associated with their extraction or production process; opting for sustainable sources of wax and other components might be more expensive in the end, but it carries great benefits too. Additionally, keep in mind any safety regulations involved in health, as some raw materials may contain potentially hazardous chemicals or pollutants that need to be declared on final product labels. Lastly, think about what type of marketing efforts will be needed around these products and build accordingly over costs related to packaging and labeling when considering your price points.

Tips and Tricks for Saving Money

1. Look for substitutions: If you’re looking to save money, consider finding a different material that can be used that is more budget friendly. For example, if you find yourself needing more wax for your candles, investing in beeswax instead of paraffin wax might be a more cost-effective option.

2. Shop on a budget: Set rules and restrictions around what you’re willing to spend on the candle making raw materials either per item or per batch. Research which items have the best price according to your needs, and don’t exceed those strict parameters no matter how tempting it may seem at the time.

3. Ask for bulk discounts: Many stores offer discounts when customers buy in bulk so ask around whether anyone you know can benefit from your purchase as well or ask shop assistants if they are able to give you any discounts on bulk orders.

4. Join candlemaker communities: There are tons of forums and online shops specifically catered towards DIY craft and Candle Making enthusiast that may post deals or provide insider information about discounted supplies. Joining these communities is an excellent resource for discovering new places to buy your ingredients at less expensive prices than what retail shops demand.

How Developments in Candle Making Technology Impact Prices

Developments in candle making technology can have a significant impact on the price of raw materials used in their production. For example, if new techniques are developed to produce more candles with the same amount of raw materials, the price may begin to decline due to increased availability. Additionally, advancements that reduce labor costs will also lead to a reduction in price.

The most obvious benefit of these changes is a decrease in spending for materials when manufacturing candles. This could equate to larger profits or savings for businesses, which can then be reinvested into further innovation and development or other areas of their operations and growth. Consumers may also benefit from this since the cost savings would likely be reflected at point-of-sale in retail outlets or online stores.

On a societal level, cheaper prices means that people can purchase more items to brighten up their living spaces and enjoy aromatic fragrances without worrying about an exorbitant cost. It may also encourage more individuals to take up candle making as a hobby due to being able to purchase large amounts of supplies for less money.

However, there are some consequences that need to be acknowledged due to these developments – namely, suppliers of candles and associated components (such as wax, wicks and molds) may struggle with reduced revenue and even decide to retire entirely due to arriving competition from newly emerging participants with access to better technologies. Further still, niche producers who favor handmade processes over industrialized machinery will eventually become replaced by major manufacturers offering competitively priced products made through cutting edge assembly lines.

Examples from the Candle Making Community

Case Studies: Candle making is a satisfying and rewarding endeavor. To determine what raw materials, supplies and equipment are required to make certain types of candles, reviewing successful candle-making case studies can be helpful. These studies provide insights into the cost analysis of different methods used by entrepreneurs in their candle-making businesses. They also highlight the unique recipes and techniques used to create wonderful scented or decorative candles from a variety of raw materials, such as waxes, wicks, fragrances and dyes. Cost estimation can often be determined based on industry standards as well as successful product pricing strategies employed by experienced designed.

Cost Analysis: A detailed cost analysis of the various raw materials and other related supplies used in making specific types of candles should be conducted to prevent financial loss due to overpricing or underestimating expenses. Suppliers can be contacted directly to obtain information about their costs for each component part that goes into the manufacture of a particular type of candle. When pricing candles, all elements must be taken into account, including labour costs along with overhead expenses such as marketing efforts or packaging needs. Competitive market research should also inform decisions around pricing to ensure that your final retail prices remain competitive with like products.

Conclusion

The price of candle-making raw materials is an important factor when it comes to determining the cost of a candle. This blog post detailed various factors that can drive up the cost of candle-making raw materials, including increasing demand, limited availability, fluctuating exchange rates and transportation costs. By understanding the factors influencing the price of wax, wicks and fragrances, one can anticipate how much they are likely to pay for their materials each year. Looking ahead, it’s important for candle makers to stay on top of industry trends so that they can adapt their product lineup and keep up with changes in raw materials prices.

In summary, this blog post has provided an important overview of factors influencing the cost of candle-making raw materials. It is clear that increased demand, limited availability coupled with fluctuating exchange rates and transportation costs can all contribute to a rise in prices. To remain competitive,, candle makers should stay informed about pricing trends and make adjustments accordingly by reading industry news and taking stock of their current inventory levels. With due diligence on these points, candle makers should be able to maintain pricing stability even with unpredictable material costs.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.