The Candle Making Wick Chart is an invaluable reference for all candle makers. It provides a comprehensive and highly detailed way to compare and understand the differences between many popular wicks in order to ensure that when a candle is made, it will be produced with the best results.

The chart covers everything from the diameter of the wick, the type of wax used, how much heat or energy it takes to ignite, and even the expected burn time when lit. As such, looking at a Candle Making Wick Chart can allow one to make informed decisions about which wick would be preferable to use for their particular project.

When using a Candle Making Wick Chart, the most important element to take into account is what kind of wax you are using. Different types of waxes have different properties – some may require higher melting points than others or more energy input.

Additionally, some waxes require differently sized wicks than others, so you should always make sure you check your Candle Making Wick Chart before deciding on a specific size or style of wick. Once you’ve found your wax type along with its respective wick size in the chart then you can pinpoint the other details that go hand-in-hand such as burning time and how quickly your candle will burn down.

Another useful feature that is often included in a Candle Making Wick Chart are diagrams showing how larger size fuel sources are used depending on certain temperatures around the wick instead of using multiple smaller ones. This could be helpful for those looking to create scented candles where they want thicker smoke output that shows off more closely with each note in their fragrance blend versus having thin smoke trails coming out of multiple smaller fuel sources simultaneously.

This allows for more control over what kind of scent experience they are providing customers with through their products without having difficulties getting too large of a flame from single tiny flames placed separately all over their container candles.

Regardless if one is just starting out making candles or has been doing so professionally for some time; having access to the right information could mean all the difference between success and failure within this industry. Luckily with detailed information provided in both written form as well as visual illustrations through a Candle Making Wick Chart it has become much simpler for starters and experts alike to confidently choose which type and size of wick works best for them.

Introduction to Candle-Making Basics for Beginners

Candle-making is a fun and satisfying hobby with a variety of potential creative applications, whether it’s a calming home project or crafting unique gifts for friends and family. It can be as simple or complex as one likes, depending on the desired outcome. One of the most important aspects of candle-making is the right wick for each type of wax.

Using a wick that is too thick may cause excessive smoke when burning, while using one that is too thin will result in an uneven burn pool. A proper wick chart should be consulted to ensure a successful candle burn.

What To Know Before You Start

When starting off with candle-making, it’s important to understand basic terminology as well as what materials are needed. Terms like “core/cored” vs “coated” refer to wick composition while wax types include soy, beeswax, and paraffin (among others). Many craft stores carry routine supplies such as thermometers and containers however some items like specialty waxes may need to be sourced online.

Candle making also typically requires heat resistant utensils such as spoons and double boilers for melting the wax. Lastly, access to ventilation such as an open window or fan can be beneficial while working with hot mixtures involving fragrances or wax emission.

Choosing The Right Wick For Your Ember

For optimal results when designing your own candles, it’s best to consult a wick size chart before beginning any project. The chart lists various types of common wicks alongside recommended container sizes along with types of wax being used for reference purposes.

It’s important to keep in mind that certain elements such as adjusting fragrance concentrations within scent prevents may alter suggested sizes so always monitor or adjust size accordingly based off prior experience once the liquid has cooled down enough for safety reasons through careful feedback/experience monitoring after initial trial runs using a small batch set-up.

The chart should help identify which size works best for each type of candle by nature of its helpful categorisations based upon variables involved (i.e jar size/wax type). Waxes have different melting points due to their chemical formulation so using the correct sized wick is essential in order to receive an efficient burn when lit up.

With some care taken into consideration such as making sure the wicks are sitting correctly at the center prior dipping each embers in melted wax times appropriately – you can make beautiful candles without too much fuss put forth from your end.

What is a Wick Chart and Why is it Important?

Wicking, or the ability of a candle flame to draw wax up itself, is essential for candles to burn in an even and safe manner. A Wick Chart is essentially a guide which helps candle makers determine which type and size of wick works best for different candle types and sizes. It also allows for adjustments to be made so that the ideal amount of fuel can be directed into the flame.

Utilizing a Wick Chart when making candles will ensure that your candles perform optimally and predictably. Using the wrong size wick can have disastrous consequences, such as excessive smoking or an unevenly burning flame – both of which compromise safety and can create unpleasant odours from burning carbon dioxide rather than oxygen.

How Does a Candle Maker Use a Wick Chart?

Using a Wick Chart is relatively simple. After determining candle type, diameter, fill weight – these are all well documented in many great books devoted to candle making – you simply find them on the chart, locate your corresponding wick number then purchase it. The sizes quoted are nominal values but some suppliers mark wicks with either actual diameters or indicate core/braiding ratios such as 10/0 HTP core/braiding.

To save time preparing your own charts we recommend using one of the following:

- CD Alloys Wick Calculator

- Lagunamoon Wick Position Calculator

- North Country Candles Wax Melt Calculator

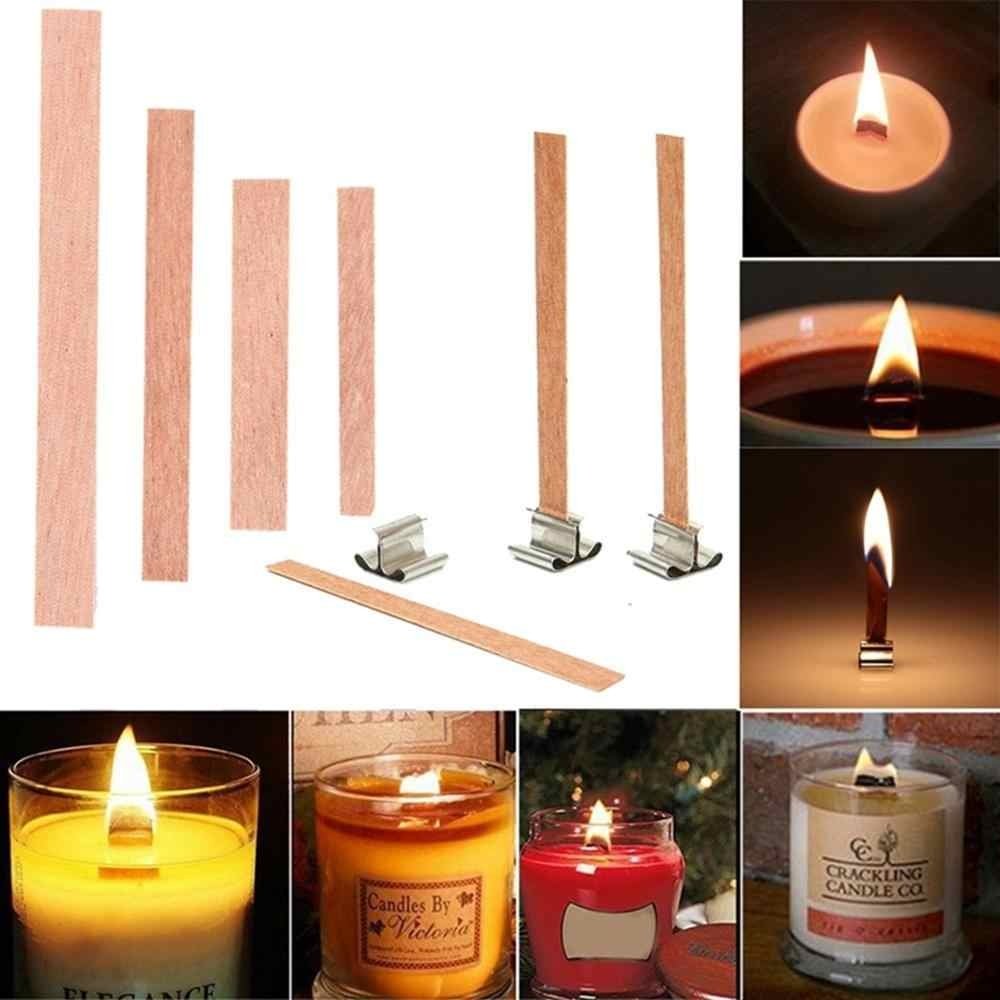

Understanding Different Candle Wicks and Their Benefits

Candle wicks vary depending on the heat and usage requirements of different types of candles. Different candle waxes will require specific burning temperatures, so certain wicks are better suited to particular types of candles. The candle making wick chart helps users identify which type tips should be used to make the best quality candle.

To find out which wick is right for you, it is important to consider the following criteria:

- Burn temperature;

- Smoke output;

- Longevity/burning time;

- Strength/Holding Ability.

Each of these qualities will need to be taken into account when choosing the best wick for a given type of wax and your personal preferences. Wicks that have higher burn temperatures may produce more soot than those with lower burn temperatures.

Additionally, some materials will last longer than others depending on their composition and exposure to the heat from the flame. Higher strength or holding ability may also be necessary if you are using dense-like container candles or larger diameter pillars.

The thickness or denier number associated with a wick can provide additional insight into its performance capabilities. Generally speaking, as denier numbers decrease it indicates that less material is being used in the construction of the wick giving it greater flexibility and increased capacity for speed when establishing a balance between fuel source (wax) and potential output (flame).

For example, a 50 Denier wick or a 240HT would generally offer faster consumption rates than 100Denier or 150HT options respectively but there are commonly exceptions to this rule based on how they are made i.e., materials used in construction).

Understanding Measurement Differences in Candle Wicks

When making a candle, it is important to understand the measurement differences in candle wicks. A single candle wick has components which measure differently, and this correlates to the properties of each particular wax type. The key measurements for wicks include width, length, diameter, heat resistance, and degradation.

The size of the wick is determined by measuring its width, or breadth. This measurement is generally expressed in millimetres (mm). The width of a wick will determine the amount of flame created when lit. Wider candles will create larger flames, reducing quickly as they burn and offering minimal scent strength. On the other hand, narrower candles have smaller flames that take longer to disperse and offer stronger scents once burned.

In addition to width measurements, the length and diameter must be taken into account when determining an ideal size for a wick. Length measurements are usually determined by centimetres (cm), while diameter can be expressed either in cm or mm.

The heat resistance and degradation rate of a particular wax type should also be taken into consideration when choosing a appropriate sized wick; if too much heat danger or quick weakening of consistency is achieved due to incorrect size selection then disastrous results might occur; such as large soot production upon lighting or full melt down once lit.

That said, an experienced candle maker can leverage existing charts from the internet that match specific wicks with different types of waxes to create desirable results with minimal mistakes; caution should always be observed in regards to experimentation with new materials though as unexpected issues may present themselves. As always it’s recommended to follow steps carefully outlined within an adequate tutorial guide for maximum safety in achieving best outcomes possible.

Choosing the Right Candle Wick for Your Candles

The process of making candles at home can be complicated but one of the most important steps in creating a successful candle is choosing the right wick. Having the right kind of wick will ensure that your candle burns evenly and that it smells good. This article will provide a brief overview of what to consider when selecting a wick for your candles as well as provide a candle making wick chart.

Types of Candles

When selecting your candle wick, it’s essential to first consider what kind of candle you’re making. Different types of candles require different types and sizes of wicks-such as those made out of cotton or paper-based material.

For example, tapers typically use small cotton wicks that promote an even burn, whereas container candles usually need larger wicks like those made out of paper. Additionally, beeswax candles are suggested to have a larger diameter core for their wicks to help make them last longer and perform better over time.

Size Matters

Wicks for pillar candles also come in various sizes depending on their intended use-like creating taper or container candles. When determining the size you need for your project, look for one that is just wide enough so the wax can easily melt down when it is lit but not so large that it creates an uncontrolled flame.

The same goes with length; shorter wicks may extinguish quickly while longer ones could be too difficult to control and lead to a “mushrooming” effect during burning (excess flame).

Consider Fragrance Oils

Lastly, if you plan on adding any fragrance oils or other additives into your homemade candles then be sure to choose a thick type of soy or paraffin wax since these materials hold up better in higher temperatures (as compared to beeswax). Additionally, look for specific “fragrance oil rated” wicks since these are better able to withstand high temperatures when burning and won’t get clogged by residue from the essential oils used in scented candles.

Measuring Candle Wicks for Your Candles

Making your own candles can be a rewarding and therapeutic experience, but as many inexperienced candlemakers soon discover, one wrong move can quickly ruin a set of candles. The most common mistake is making the wrong wick choices for each type of wax. Candle making relies heavily on science – knowing the right wick size to use for different types of wax, how much fragrance to use for different sizes and heights of candles, etc.

When selecting wicks there are three main things to consider: the weight of the wax container, its diameter and the length of burn time that you want your candle to have. This size selection process can be overwhelming at first but rest assured that there is a helpful guide for you: The Candle Making Wick Chart.

The Candle Making Wick Chart provides simple instructions for determining the proper size candle wick based on the weight of your wax container, measure its diameter, plus any additives like fragrance oils or dye blocks that you may add later on in the process. Simply match up your data points with those in the chart and find your ideal wick size (choose from various sizes such as CD-6 or HTP-44).

The chart is very helpful as it takes a lot of guesswork out when picking what type and size of wick to purchase.

Another invaluable tool provided by candle makers are heat guns or terpedo testers. Heat guns are designed to measure whether a particular wick is too big or too small depending on certain factors such as wall temperature, flame height, smoke production and blackening rate.

With glass containers it’s especially important to know how long to let your candle burn without only burning soot away from its edges since some materials become toxic when overheated (which might happen if using a wrong sized wick).

In addition, once you have chosen a certain type & size of wax & selected an Approximate amount of Fragrance Oil & dyeblock according to current usage rates (consulting with suppliers) then testing each individual batch is still necessary before casting into molds/tins. A good tip would be not just testing one sample; rather test several samples till get reliable results so can get an accurate opinion before creating whole production run.

Tips for Working with Candle Wicks

Making candles can be an enjoyable and satisfying experience. However, if the wick is too weak or too thick it can affect the finished product. The following tips will help you choose the right type of wick for your candle making project:

- Choose a wick that suits the size and shape of your container.

- Location is key – make sure you test your wicks in different areas of the flame to ensure even burning.

- Check if your wax requires any additives like stabilizers, stiffeners or crimp-resistant wicking to prevent ”mushrooming” at the burn site.

- The finer your wax, the finer the wick should be. Finer wicks are also more prone to curling.

To get the best results from your candle making project, it’s important to use a candle making wick chart. A candle maker’s responsibility is to achieve a correct balance between heat output and flame height, while taking into consideration safety measures for both their own and others safety. Knowing how different types of wicks perform under pressure will give you an accurate idea of what type will suit your needs.

A typical candlemaking wick chart contains five columns; Material, Candle Type, Burn Time (in minutes), Flame Shape and Height (in mm). It’s made up of categories tested with specific wax types and materials such as paper core cotton or hemp blends.

Each category has its own colour coding, so it’s easy to match them up. Generally speaking, using smaller material than desired will result in a longer lasting flame whereas bigger material than desired may cause increased sooting or smoke production whilst burning.

Under every category there are ratings ranging from 1 being a low performance/low heat output insufficiently lacing through to 5 being a high performance/high heat output with sufficient lacing (the ability to hold its form when drawn away from centre). If you’re aiming for maximum performance then look for 4-5 rated materials when searching for your ideal material in a particular category.

Recommended Candle Wicks for Different Types of Candles

Pillar

Pillar candles are often used for décor or to make a statement, and as such require an appropriate wick size. Recommended wicks for pillar candles include:

- Unbleached Cotton/Paper Core (ECO) – 6-8mm

- Square Braided Cotton – 8-10mm

- Cored Patentled Synthetic Blend – 10mm

- Braided Aramid/Metallic Core – 12-14mm

Choosing the correct material is also very important when making pillar candles. Both cotton / paper core with organic wood materials such as bamboo work best for these types of applications. The braided cotton and Aramid / metallic core also work very well to create different effects with pillars.

When CandleScience suggests wicks for pillar candles, the sizes indicated are based on wax formulations from our customer base. As each individual candle maker may add fragrances, dyes, and additives in their own way, it will still be necessary to test and adjust according to their own particular formulation(s).

Waxes used in making pillars can also have a big impact on the outcome of the finished candle.

Paraffin / palm blends are great for holding scent, colors, and having excellent burn characteristics; Beeswax blend formulations help to create clean burn that adds luxury to any decor; Soy wax blends are ideal for personalized gift giving as they cleanly release scent and colors while burning down evenly; Coconut blended waxes give true “old time” feel with crackle when burning along with strong scent throw.

No matter which type of Wax you choose it is always necessary to test all your pillars prior to production runs.

Troubleshooting Candle Wicks and What to Do if Your Candles Won’t Burn

When it comes to making quality candles, the wick is one of the most important parts of the process. If you don’t make sure that you have the right size and type of wick for your candle, then your candle won’t burn correctly. To solve this issue, you need to troubleshoot why your candle is not burning and find a solution.

The first thing to do when troubleshooting candle wicks is to make sure that you are using the correct size and type of wick in proportion to the size of your container or mold. This will ensure that your candles burn in an even manner and last for a longer period of time. You can easily find this information using a reliable Candle Making Wick Chart.

Next, make sure that you are measuring out enough wax for each pillar as well as not having too much wax pooled up at one spot on the fire area. For instance, if there isn’t enough wax in certain areas, then these spots won’t get hot enough and thus cause problems with even burning.

Lastly, check if your wick is trimmed properly for efficient combustion by snipping off ends that have been charred away or become untrimmed overtime. By doing so, it will help optimize the intensity and heat flow through your flame for an optimal burn session.

What We Can Do To Quickly Get The Results

- Use a reliable Candle Making Wick Chart.

- Measure enough wax according to the size

- Check if your wick is trimmed properly

Resources for Further Research on Candle Wicks

Candle wicks are an important part of the overall candle-making process. Ensuring that the correct type of wick is used can make the difference between a successful and unsuccessful candle-making project.

But with so many different types of candle wicks on the market, it can be difficult to choose the right one for your needs. To help alleviate this problem, many candle makers now rely on candle making wick charts that detail all the available options as well as their specifics.

The basics of a candle making wick chart include information on size, material, and burn time. The size consists of diameter measurements in millimeters or inches, depending on what unit of measurement was used for creating the chart.

While sizes vary from standard to specialized sizes, thickness generally remains uniform across brands and models for easy comparison purposes. Material is equally important depending on the type of wax being used – such as polycotton or hemp core strands – and burn time refers to how long it takes for each particular type of wick to fully consume its fuel source.

Another important feature associated with modern candle keeping wick charts is their availability online through sites like Amazon or other website retailers that specialize in everything related to candles and waxes. This makes researching various products easier than ever before and allows DIY enthusiasts to make better informed decisions about which product best suits their individual needs and projects.

A variety of electronic resources can also be turned to when conducting research on wick materials including blogs and forums dedicated specifically to this subject matter where experienced craftspeople share hints and tips about using different types of wicks in combination with certain waxes or scents for maximum effect.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.