Introduction

Setting a candle is usually a relatively simple and straightforward process, but there are a number of factors that can influence how long it takes for the wax to harden and set. Factors such as the humidity levels in the environment where the candle is located, its thickness, type of wax used, and color all play a role in influencing how quickly or slowly it will take for your candle to set. Additionally, the type of mold you use, such as an open or closed container will also make a difference. Depending on these variables, it can typically take anywhere from 30 minutes to two hours for your candle to be completely set and ready for use.

What Type of Wax

The type of wax used in making a candle will have an impact on how long it takes for the candle to set. Paraffin wax, which is most commonly used in making candles, sets fairly quickly compared to other types of wax and usually takes around 15-20 minutes. Soy wax is another common type of wax used in candles and takes slightly longer to set than paraffin; around 30-45 minutes. Beeswax and palm wax tend to take even a little bit longer than soy wax to set, approximately 45 minutes to 1 hour. When adding additional ingredients such as colorants, scents, or emollients like shea butter, this may add extra time for the candle to fully cool and harden. By taking into account all these points we can get a better idea of just how long it takes each specific kind of candle to set.

Preparing the Mold

Using the right kind of mold plays a crucial role in how long it takes a candle to set. A mold needs to be in tune and properly size for the project at hand. The bigger the project, the larger the mold should be. If too small, then when you pour the wax into the molds, it will overflow and cause potential problems with setting times. Additionally, if too big, then the wax could settle away from oxygen and cool down much slower than desired.

To prepare a candle mold before pouring wax in it, ideally it should be pre-heated either using warm air or warm water with additives like Epsom salt to add an extra element of heat transfer. This helps create an optimal environment for fast setting times depending on what type of wax is used. If paraffin is used, pre-heating can increase its softening point for easy pouring and better penetration which leads to fewer dry spots around your candles’ edges due to better evenness of heat distribution. Even an oven can be used if needed ” but care must be taken that temperatures are not too high to avoid warping/buckling/melting of some plastic containers or silicone molds that cannot take high heats as well as others may be able to provide much faster setting times and stronger scents when set correctly at higher temperatures. Ultimately it really depends on how quickly you need your candle set while still getting great results with quality scents and attractive aesthetics once cooled off completely after several hours or days (depending on size).

Choosing the Wick

When it comes to choosing a wick for your candle, one of the most important factors to consider is how it will affect the setting time. The wick acts as the flame’s source of oxygen and fuel, so it’s important to select a wick that is appropriate for your candle. Here are some types of wicks and their benefits:

• Natural fibres such as cotton or linen: These natural fibre wicks provide good air flow and avoid sooting or smoking. However, they are slower to burn and take longer for a candle to set than other types of wicks.

• Beeswax-coated cotton or hemp: These wicks are made from natural fibres coated in beeswax which allows for better burning performance, as well as providing a long lasting scent with each burn. With this type of wick, you can expect some faster setting times than with natural fibres alone.

• Synthetic fibres or metal-core alloy: These man-made materials are designed specifically to provide maximum efficiency when burning a candle. These synthetic material offer speedy setting times while still promoting sufficient oxygen flow which ensures only minimal smoking if any at all.

Selecting the right wick can greatly broaden your range of options when making candles – in terms of scents, shape, colour and more – while ensuring your desired results in terms of burn rates and other properties like scent throw or visibility. Knowing which type of wick works best with your particular project will help you achieve the perfect set time without overburning or underburning your candles.

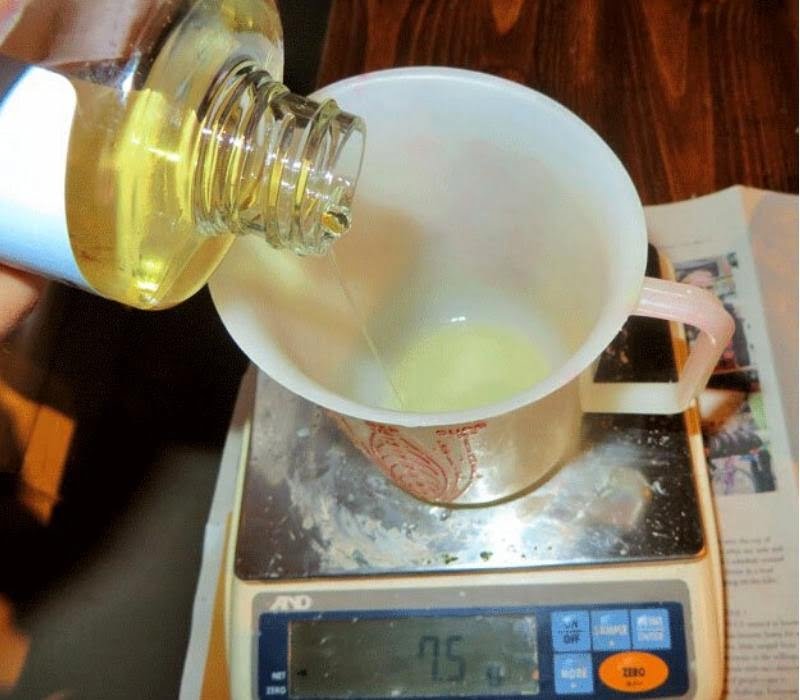

Melting the Wax

The process of melting the wax for a candle can vary depending on a few factors, such as the type of wax being used and the tools that are available. Generally speaking, it takes about 10-15 minutes to melt enough wax to fill a standard sized candle container. The temperature range should typically be between 180-200 degrees Fahrenheit in order to achieve the optimal results. Too low of temperatures will cause the wax to cool too quickly, leading to a weak candle with poor scent throw; whereas too high of temperatures can result in scorching or smoking on the surface of the wax.

Once melted, it is best practice to filter and strain the wax prior to pouring into your vessels or molds. This helps remove any debris present in the wax and ultimately creates a better looking finished product. After pouring all of your containers, they need time to set up and harden before you move them. Depending on ambient temperature, this can take anywhere between 2-5 hours for normal sized votives or tarts and 6-12 hours for cylinders or pillars. When setting candles it is important not overfill your vessels as this often results in improper burning and tunnelling.[1] To prevent tunneling you should always leave 1/4 inch from the top of each container so that the flame has room to flicker without consuming all of the available fuel too quickly.

Trimming the Wick

When trimming the wick of a candle, it is important to ensure that the wick is not too short and not too long. The ideal length for a candle’s wick should be approximately 1/4 of an inch or 5mm. A shorter than desired wick will affect how well the candle burns as it can struggle to draw in enough oxygen to keep the flame lit; if left longer than desired, the flame will become more prominent and run hotter, risking sooting and uneven burning.

To achieve a 1/4 of an inch or 5 mm length, use sharp scissors, nail clippers or a specialised tool made for trimming the wick (such as a Wick Trimmer), and begin by soaking up any remaining melted wax from around the area where you are about to snip with some kitchen paper towels before making your cut. Once you’ve snipped away all that is required proceeding to fill in any gaps with additional melted wax will help secure the newly trimmed wick in place. Allowing slight cooling time after all this is beneficial prior lighting.

Once you’ve taken care of your candles by following these steps and checked on whether their 1/4 inch length has been achieved (as previously mentioned), they are ready to be lit! Depending on how much time you spend on achieving your ideal trimmed lengths, setting up your candles can take anywhere between fifteen minutes to an hour or more depending on how many you are preparing.

Waiting for the Candle to Set

When it comes to the time it takes for a candle to set correctly after being poured, it depends mainly on a few factors. The size and design of your candle will have an effect on the time it takes for the melted wax to cool down and solidify into an even shape. Generally speaking, larger candles with more intricate designs tend to take longer for the wax to cool down and harden. A good rule of thumb is that if you allow twice as much time as the time you spent pouring the candle in order for it to become firm and frosted, then you should be fine.

Another factor that may affect how long it takes a candle to settle is its environment. If your place has lower ventilation or higher humidity levels, then this can result in slower cooling times since these conditions prevent any natural air circulation from taking place as well as capture moisture more easily than open spaces. Careful consideration should be taken when choosing where to pour your candles since this will greatly affect their performance in terms of setting properly.

Best practices also recommend that consumers allow their candles some extra time to dry and settle before they light them up; usually around 24 hours after they have been poured. It’s important not to skip this part because poking wicks too soon in attempt of igniting the candle could cause serious issues such as tunneling or leaking wax from underneath its surface.

By taking all these measures into account, one can expect a well-made candle using high-quality ingredients and good pouring practices to completely set within 4-24 hours depending on its design and size, but always allowing some extra drying time at least before use is highly recommended.

Conclusion

When making a candle, doing it properly and being patient is key. It takes attention to detail and the right safety measures to get the perfect pour. Properly preparing the materials, pre-heating the wax, measuring and melting it all at a low heat helps ensure that you have a well-made candle. Once poured into the desired mold or container, let your candle cool completely before removing it from the mold or container – this can take up to 24 hours depending on factors such as weight and size of the candle. After inflation your candle should be set enough for trimming any excess wick off around 1/4″ above the top surface of the wax. When followed correctly these steps will help you create an excellent quality candle from start to finish.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.