When it comes to candle making, selecting the right wick size is paramount. The size of the wick has a significant impact on various factors such as how well the candle burns, its efficiency, and even its safety. The choice of wick size determines how much wax will be consumed during each burn and how the fragrance is released into the air. Therefore, understanding the importance of selecting the correct wick size is crucial for any candle maker.

There are several key factors to consider when it comes to selecting a wick size for your candles. One critical variable is the type of wax you are using. Different types of wax have different burning properties, so choosing an appropriate wick size that matches your specific wax type can make all the difference in achieving optimal performance.

Another factor to consider is the container size. The diameter and depth of your candle container directly influence which wick size will work best. Using a wick that is too small or too large for your container can lead to issues such as uneven burning or excessive smoking.

Additionally, considering the fragrance load is essential when picking a suitable wick size. The amount and type of fragrance used in your candles can affect how evenly they burn and how effectively they release scent into the surrounding area. Adjusting the wick size accordingly ensures an ideal balance between fragrance throw and combustion performance.

What factors to consider when selecting a wick size for candle making

When it comes to selecting the right wick size for your candle making project, there are several factors that need to be taken into consideration. These variables can have a significant impact on the performance and overall quality of your candles. Understanding these factors and their influence on wick size selection is crucial for achieving optimal burning performance and safety.

One of the primary factors to consider when choosing a wick size is the type of wax you are using. Different types of wax have different melting points and characteristics that can affect how the candle burns. For example, soy wax tends to burn cooler and requires a larger wick size compared to paraffin wax. Beeswax, on the other hand, has a higher melting point and typically requires a smaller wick size.

The size and shape of your container also play a significant role in determining the appropriate wick size. The diameter of the container is particularly important as it affects how efficiently heat is transferred from the flame to melt the surrounding wax.

A general guideline is to choose a wick that matches or slightly exceeds the diameter of your container. Choosing too small of a wick can result in poor burn quality, while choosing one that is too large may lead to excessive smoking or mushrooming.

Additionally, the fragrance load in your candle should also be taken into account when selecting a wick size. Fragrances with higher oil contents can affect how well the candle burns and may require a larger wick for proper scent throw. It’s important to experiment with different wick sizes when using fragrances to find the right balance between scent throw and burn performance.

To summarize, when selecting a wick size for candle making, it’s essential to consider factors such as wax type, container size, and fragrance load. Each of these variables has an impact on how well your candle will perform during burning. Taking the time to understand these influences and conducting test burns will help you choose the right wick size for your specific candle making project.

| Factors to Consider | Influence on Wick Size Selection |

|---|---|

| Wax Type | Different types of wax have different melting points and characteristics that require specific wick sizes. |

| Container Size | The diameter of the container affects heat transfer and determines the appropriate wick size. |

| Fragrance Load | The amount and type of fragrance used can influence the necessary wick size for optimal scent throw and burn performance. |

Importance of proper wick size

Enhanced Burn and Scent Throw

Selecting the proper wick size for your candle plays a crucial role in achieving optimal performance and safety when burning. Using the correct wick size ensures that your candle burns evenly, minimizing issues like excessive smoking or tunneling. Additionally, it allows for efficient melting of the wax, leading to a steady and consistent flame.

A common misconception is that using a larger wick will result in a stronger scent throw. However, this is not always the case. In fact, using a wick that is too large for your candle can cause the fragrance oils to evaporate too quickly, resulting in a weak scent throw. On the other hand, using a wick that is too small may not release enough heat to effectively disperse the fragrance throughout the room.

When selecting the appropriate wick size for your candle, consider factors such as fragrance load, container size, and wax type. Each of these variables can influence how efficiently the candle burns and how well it disperses fragrance. By choosing the right wick size for your specific needs, you can enhance both burn performance and scent throw, creating an enjoyable experience for yourself or those who purchase your candles.

Safety Considerations

Selecting the proper wick size goes beyond just ensuring optimal burn performance; it also plays a critical role in maintaining safety during candle burning. When using a wick that is too large for your candle, you risk creating an excessively high flame that can lead to accidents or even fire hazards.

A properly-sized wick allows for controlled burning without creating an overly high or unstable flame. It prevents overheating of the container or wax which could lead to cracking or shattering. By avoiding these safety concerns through proper wick selection, you can enjoy peace of mind while enjoying your candles without worrying about potential risks.

It’s important to note that safety guidelines should always be followed alongside proper wick size selection. These guidelines include never leaving a candle unattended, keeping candles away from flammable materials, and placing them on a heat-resistant surface. By combining these safety precautions with the appropriate wick size, you ensure not only an enjoyable candle experience but also a safe one.

Increased Longevity of Candle

Selecting the correct wick size is also essential for maximizing the longevity of your candles. Using a wick that is too large can cause the candle to burn too quickly, resulting in premature depletion of your product. Conversely, using a wick that is too small may result in a poor wax melt pool formation, leading to an inefficient use of wax.

By choosing the appropriate wick size, you can promote a steady and controlled burn that prolongs the life of your candle. This allows customers or yourself to enjoy many hours of burning time before needing to replace or repurchase the candle. The ability to create long-lasting candles not only benefits consumers by offering more value for their money but also contributes to sustainable and eco-friendly candle making practices.

Wick size selection based on container diameter

To ensure proper candle burning and optimal performance, selecting the right wick size based on the container diameter is crucial. The diameter of the container determines how much heat needs to be generated by the flame to melt and release the wax, ultimately affecting how well the candle burns. Here is a detailed breakdown of how to determine the ideal wick size based on the diameter of the container being used:

- Measure the diameter: Start by measuring the inside diameter of your candle container at its widest point. It’s important to be precise in your measurements for accurate wick selection.

- Use a wick chart or calculator: Many reputable candle making suppliers provide wick charts or online calculators that recommend appropriate wick sizes based on container diameter. These tools take into consideration various factors like wax type and fragrance load, ensuring accurate results.

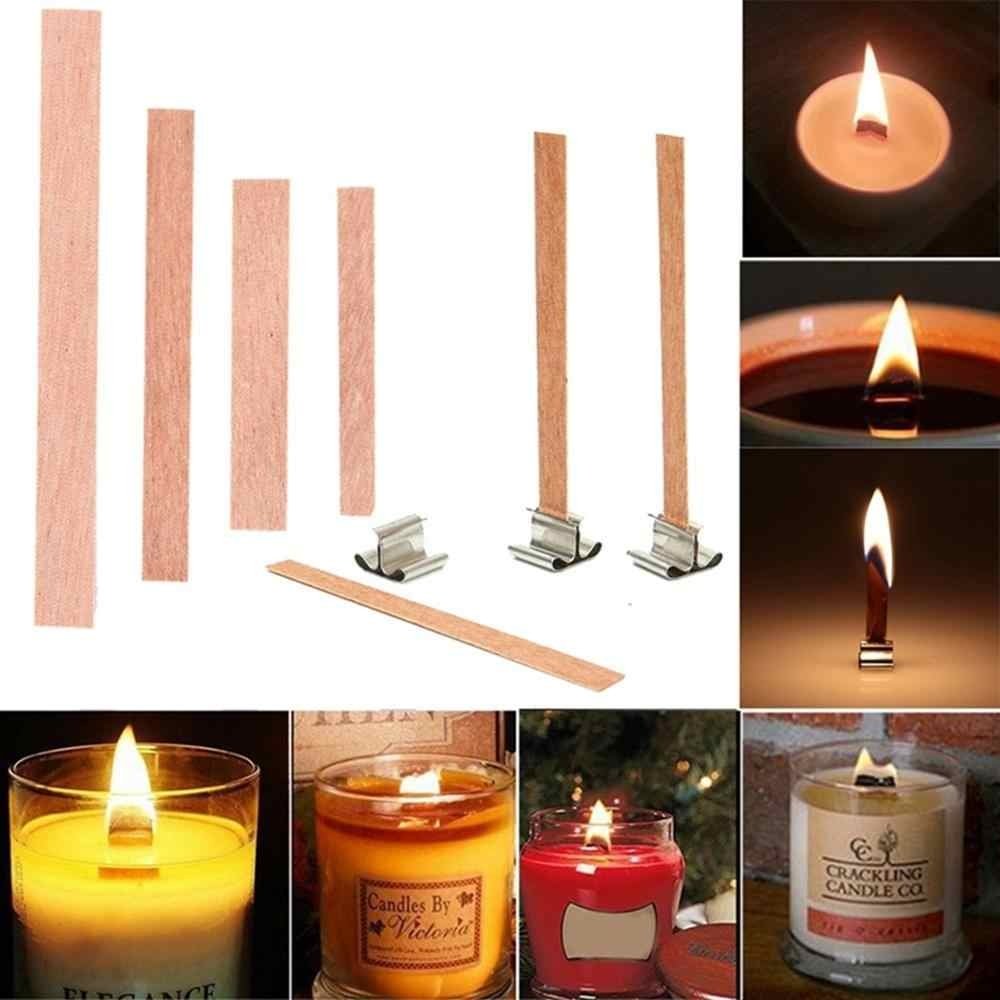

- Consider different wick types: Wicks come in various materials, such as cotton, paper-core, or wooden-core, each with its own burning characteristics. Depending on your preference and specific requirements, explore different wick types recommended for your chosen container diameter.

- Test burn before finalizing: Once you have selected a suitable wick size based on your container diameter, conduct test burns to verify its performance. Light the candle and observe if it produces a steady flame, melts the wax evenly across the surface of the container, and maintains self-trimming properties.

Remember that larger containers require bigger flames for a complete melt pool formation, while smaller containers need smaller flames to prevent excessive heat buildup. Adjustments may be needed if you notice tunneling (when wax accumulates around edges) or poor melt pool formation during test burns.

By following these steps and taking into account any additional recommendations from trusted sources and suppliers, you can confidently select an appropriate wick size that will help achieve satisfactory burning results in candles of various container diameters.

Wick size selection for different types of wax

When it comes to selecting a wick size for candle making, one important factor to consider is the type of wax being used. Different types of wax have different characteristics that can affect the burning performance of the candle. Whether you’re using soy, paraffin, or beeswax, it’s crucial to understand the specific considerations for each type when choosing the appropriate wick size.

Soy Wax

Soy wax has gained popularity in recent years due to its natural and eco-friendly properties. When selecting a wick size for soy wax candles, it’s important to consider the unique qualities of this type of wax. Soy wax tends to have a cooler burn and may require a larger wick size compared to other types of wax.

This is because soy wax needs more heat and energy to properly melt and release fragrance. A larger wick can help provide an optimal melt pool and ensure an even burn throughout the candle.

Paraffin Wax

Paraffin wax is widely used in candle making due to its affordability and versatility. When choosing a wick size for paraffin wax candles, it’s essential to keep in mind that paraffin has a higher melting point compared to other waxes.

This means that a smaller wick size may be needed for efficient burning as paraffin generally produces less heat than other waxes. Additionally, since paraffin can release more soot than other types of wax, selecting a proper wick size can help minimize sooting issues and contribute to cleaner burning.

Beeswax

Beeswax is known for its natural golden color and sweet scent. It also has some unique characteristics that should be considered when choosing the right wick size. Beeswax tends to have a high melting point which requires a larger flame for proper combustion.

Therefore, selecting a properly sized wick is crucial to ensure that the beeswax candle burns evenly and doesn’t tunnel. It’s also important to note that beeswax has a lower heat tolerance compared to other waxes, requiring careful wick selection to prevent overheating and potential safety hazards.

By understanding the specific considerations for different types of wax, candle makers can make informed decisions when selecting the appropriate wick size. Taking into account the unique qualities and burning properties of soy, paraffin, or beeswax will help ensure optimal performance and safety in candle burning experiences.

Adjusting wick size for fragrance load

When it comes to candle making, fragrance is a crucial component in creating an enticing and enjoyable experience for candle lovers. However, the addition of fragrances can significantly impact the burning performance of a candle and even affect its safety. That’s why it is important to adjust the wick size based on the amount and type of fragrance being used.

The scent throw, or the strength at which the fragrance is released into the air when the candle burns, is directly influenced by the wick size. If the wick is too small for the fragrance load, it may not be able to properly melt all of the wax, resulting in poor scent throw. On the other hand, if the wick size is too large, it can lead to excessive smoking and soot buildup.

To determine the ideal wick size for your specific fragrance load, it’s recommended to refer to wick manufacturer charts and test different options. These charts provide guidance on selecting a suitable wick based on factors such as wax type, container diameter, and fragrance load percentage. Additionally, testing different wicks with varying fragrance load percentages can help find the perfect balance between scent throw and burning performance.

| Fragrance Load Percentage | Recommended Wick Size |

|---|---|

| 0-5% | Small/Tea Light Wick |

| 5-10% | Medium Wick |

| 10-15% | Large Wick |

| Above 15% |

It’s important to note that the type of fragrance used can also impact the burning performance. Some fragrances, such as those with high oil content or heavy botanicals, may require a larger wick size to ensure proper melting and fragrance dispersion. Conversely, lighter fragrances may work well with smaller wick sizes.

By adjusting the wick size based on the fragrance load and type, candle makers can achieve optimal scent throw and burning performance in their creations. Conducting burn tests with various wicks and fragrance loads will help determine the best combination for each specific candle project. Remember that finding the right balance is crucial for ensuring both an enjoyable scent experience and a safe burning candle.

Testing and troubleshooting wick size selection

Testing and troubleshooting wick size selection is an essential step in the candle making process to ensure optimal performance and address any issues that may arise. Conducting burn tests allows candle makers to observe how the chosen wick size interacts with the specific wax, fragrance load, and container being used. This section will provide step-by-step instructions on how to conduct burn tests and troubleshoot common issues related to wick size.

To begin, gather a few candles made with different wick sizes that you want to test. It’s recommended to test at least three different wick sizes to compare their performance. Choose candles that are similar in container size, wax type, and fragrance load for accurate results.

First, trim the wicks of all the candles to approximately ¼ inch before lighting them. This ensures a consistent starting point for each test. Place each candle on a heat-resistant surface in an area free from drafts or other sources of air disturbance.

Light each candle simultaneously and observe their performance. Pay attention to how evenly the wax melts and forms a pool around the wick. Look out for signs of excessive smoking or soot formation as well.

After about 1-2 hours of burning time, analyze the melt pool formed by each candle. If there is poor melt pool formation where some parts of the wax have not melted while others have, it indicates that the wick is too small for your specific combination of factors (wax type, container size, fragrance load).

If there is excessive smoking or soot formation, it suggests that you might be using a wick that is too large for your particular situation.The soot can darken the wax and affect its overall appearance.

Based on your observations during these burn tests, make adjustments accordingly. If you find that there is poor melt pool formation or excessive smoking, consider trying a larger-sized wick. Conversely, if you notice uneven burning or high flames causing flickering or rapid burn, try using a smaller-sized wick.

By conducting thorough burn tests and troubleshooting any issues related to wick size, candle makers can ensure that their candles burn safely and optimally. Remember to keep detailed records of your testing process, including the specific variables involved, so that you can refer back to them for future candle making projects.

Utilizing wick size charts and resources

Utilizing wick size charts and resources can be incredibly helpful for candle makers in selecting the correct wick size for their specific candle projects. These charts and resources provide valuable information and guidance, making the process of choosing the right wick size much easier. Here are some trusted wick size charts and online resources that can assist you in your candle making journey:

- Wick Size Charts: Many companies and suppliers that specialize in candle making offer wick size charts on their websites. These charts typically provide recommendations for different container sizes, wax types, and fragrance loads. They often include detailed information on which wick to use based on these factors, making it a great starting point for selecting the appropriate wick size.

- Online Forums and Communities: Engaging with online forums and communities dedicated to candle making is another excellent resource for finding advice and recommendations on wick size selection. These platforms allow you to connect with experienced candle makers who are more than willing to share their knowledge and expertise. You can ask questions, discuss specific challenges or concerns, and learn from others’ experiences to make informed decisions about your own candles.

- Wick Testing Kits: Some companies offer comprehensive testing kits that include a range of different wicks sizes, allowing you to conduct burn tests before committing to a larger quantity of a particular type of wick. These kits help you determine the most suitable wick size for your specific combination of wax type, container size, fragrance load, and other variables.

- Candle Making Books and Guides: Investing in reputable candle making literature is another valuable resource for learning about different factors that influence wick selection. These books often provide detailed explanations, practical tips, case studies, and even step-by-step instructions on conducting burn tests to guide you through the process effectively.

When utilizing these charts and resources, it’s important to remember that they serve as guidelines rather than strict rules. Each candle maker’s unique combination of variables may require deviations from the recommended wick sizes. It’s always a good idea to conduct burn tests and monitor the performance of your candles to ensure the wick size is producing the desired results.

By taking advantage of these trusted wick size charts and resources, candle makers can save time and effort in selecting the correct wick size for their specific candle projects. They provide valuable guidance, knowledge, and support that can contribute to successful and enjoyable candle making experiences.

Conclusion

In conclusion, selecting the correct wick size is a crucial step in candle making that directly affects the performance and safety of the finished product. Throughout this article, we have explored various factors to consider when choosing a wick size, including wax type, container size, fragrance load, and even the diameter of the container. Each of these elements plays a significant role in determining the ideal wick size for your candle.

By using the appropriate wick size, you can ensure optimal burning performance and prevent potential safety hazards such as excessive smoking or poor wax melt pool formation. It is essential to conduct burn tests and troubleshoot any issues that may arise related to wick size selection. This will help you identify any necessary adjustments that need to be made for achieving the desired scent throw and burning performance.

To assist you in this process, various resources are available online, including trusted wick size charts specifically designed for different types of wax and containers. These tools can be invaluable in guiding you towards selecting the right wick size for your unique candle projects.

In summary, taking the time to carefully select a suitable wick size will greatly contribute to successful and enjoyable candle making experiences. By considering all relevant factors and utilizing available resources, you can create candles that not only look beautiful but also provide a safe and satisfying burning experience for yourself or your customers.

Frequently Asked Questions

How do I know what size wick for my candle?

When determining the appropriate size wick for your candle, there are a few factors to consider. The size of the wick will depend on the diameter of your candle vessel or mold. A general rule of thumb is to choose a wick that is roughly the same width as your candle container, ensuring that it provides sufficient heat to melt the wax evenly across the entire diameter.

Additionally, take into account the type of wax you are using and any additional additives or fragrances that may affect how the wick burns. It’s always recommended to consult wick manufacturer guidelines or conduct burn tests to find the ideal size for your specific candle-making project.

What is the rule for candle wicks?

The rule for candle wicks involves striking a balance between providing enough heat to fully melt and consume the wax while avoiding excessive flame height or soot production. A well-chosen wick should create a steady, teardrop-shaped flame with minimal flickering. If a wick is too small, it may struggle to keep up with melting the wax, resulting in tunneling or incomplete burning.

On the other hand, if a wick is too large, it can produce an excessively tall flame that poses safety hazards and may generate excessive smoke and soot. To ensure optimal performance, it’s important to select a wick size that suits your candle’s specific characteristics.

What is the best wick to use when making candles?

The best wick to use when making candles depends on various factors such as the type of wax being used, any additional additives in the formula (e.g., fragrance oils), and the desired burn characteristics for your candle. Cotton cored wicks are commonly used in many types of candles due to their versatility and reliability. They are available in different sizes and offer good burning performance in various wax types.

However, there are also specialty wicks designed for specific applications such as soy wax or beeswax candles. These specialized options account for different requirements unique to each type of wax, maximizing burning efficiency and reducing potential issues such as mushrooming or excessive carbon buildup. Ultimately, it’s important to experiment with different wick types and sizes to find the best match for your specific candle-making needs.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.