When it comes to making candles, using a wick bar is an essential technique that can greatly enhance the final product. A wick bar is a simple yet invaluable tool that helps maintain the position and stability of the wick during the pouring and curing process. By providing reliable support, it ensures that your candles burn evenly and consistently from start to finish.

A wick bar serves as a guiding mechanism for keeping the wick centered and straight within the candle container. This is crucial because an off-center or crooked wick can result in uneven burning, tunneling, or even extinguishment of the flame. With a wick bar properly positioned, you can achieve beautifully crafted candles that not only look aesthetically pleasing but also provide hours of delightful aroma and illumination.

Consistency is key when it comes to candle making, and a wick bar plays a pivotal role in achieving this goal. By securing the wick in place with precision, it guarantees consistent burning throughout the entire lifespan of the candle. No more worrying about uneven melting or wasted wax – with a well-utilized wick bar, you can create high-quality candles that bring joy and relaxation into any space.

In this article, we will delve into everything you need to know about using a wick bar when making candles. From understanding different types of wicks for various candle sizes to step-by-step instructions on preparing and positioning the wick bar correctly, we will equip you with all the knowledge necessary to incorporate this essential tool into your candle making routine.

Get ready to take your candle making skills to new heights as we explore how to use a wick bar for perfectly crafted, long-lasting candles.

Understanding Wick Sizes and Selections for Different Candle Types

Choosing the right wick size is crucial when it comes to candle making. The size of the wick determines how much wax the flame consumes, which directly affects the burn quality and overall performance of the candle. To ensure that your candles burn evenly and efficiently, it is important to understand how to select the appropriate wick size for different candle types.

When determining the correct wick size, consider the diameter of your candle. The general rule of thumb is that for every inch of diameter, you should use a wick that has a certain thickness. For example, a candle with a 2-inch diameter would require a thicker wick than a candle with a 1-inch diameter. It is essential to match the wick’s thickness to the size and shape of your candle for consistent burning.

Aside from thickness, it is also important to consider the material of the wick. The most commonly used material for candle wicks is cotton as it burns cleanly and does not produce any unwanted soot or smoke. However, there are other options available such as hemp or wood if you prefer natural alternatives. Each material has its own burning properties and may work better for specific types of candles or desired effects.

To further assist in selecting the appropriate wick size and material, there are resources available such as online calculators, charts, and guides specifically designed for this purpose. These tools take into account various factors such as wax type, fragrance load, and container size to help determine which wick option will work best for your specific candle-making project.

By taking the time to understand wick sizes and selections for different candle types, you can ensure that your candles burn evenly and consistently every time. Choosing the right wicks based on diameter and considering materials will greatly enhance your candle’s performance while providing a satisfying burning experience for yourself or anyone who enjoys your homemade candles.

Preparing the Wick Bar

When it comes to candle making, using a wick bar is an essential step in ensuring that your candles burn evenly and consistently. Preparing the wick bar correctly is crucial for the success of your candle making process. In this section, we will provide you with step-by-step instructions on how to prepare the wick bar properly.

- Gather the necessary materials: Before starting the setup process, make sure you have all the required materials on hand. This includes the wick bar itself, as well as any accessories such as clips or adhesive that you may need to secure the wick.

- Assemble the wick bar: Start by determining the desired length of your wick bar based on the size of your candle container. Trim down the wick bar accordingly, if necessary. Then, insert one end of the wick into one hole of the wick bar and pull it through, leaving about 2-3 inches extending out from that end. Repeat this process for each hole in the wick bar.

- Secure the excess wick: Once all ends of the wicks are through their respective holes in the wick bar, take those excess lengths and secure them together using a clip or by tying them together with twine. This will prevent any movement or shifting during pouring and cooling.

- Consider safety precautions: While preparing your wick bar, it’s important to ensure your work area is clean and free from any flammable materials. Additionally, be cautious when handling sharp objects such as scissors or cutting tools while trimming down your wick bars.

By following these step-by-step instructions for preparing your wick bar correctly, you can lay a solid foundation for creating beautifully burning candles. Next up, we’ll explore different methods for securing the wicks to the prepared bars to further enhance their stability during pouring and cooling processes.

Securing the Wick to the Wick Bar

When it comes to making candles, securing the wick to the wick bar is an essential step that ensures the wick remains in place during the pouring and cooling process. There are different methods you can use to secure the wick, depending on your preferences and the materials you have on hand. In this section, we will explore some popular techniques for securing the wick to the wick bar.

Using Clips:

One common method of securing the wick is by using clips. Clips are small metal or plastic accessories that can hold the wick in place. To use this method, start by placing a clip onto one end of your wick. Then, slide the other end of the clip onto the wick bar, ensuring that it fits snugly. This will keep your wick straight and centered throughout the candle-making process.

Using Adhesive:

Another option for securing your wick is by using adhesive. This method involves applying adhesive, such as hot glue or double-sided tape, directly onto one end of your wick and attaching it to the wick bar. Make sure to apply enough adhesive so that it forms a strong bond between the wick and bar but be careful not to use too much that it affects how tightly you can stretch the wick across your mold.

Experimenting with different methods:

Every candle maker has their preferred way of securing a wick to a wick bar. It’s important for you to experiment with different techniques until you find what works best for you and produces consistent results.

Some may prefer using clips due to their simplicity and ease of use while others may opt for adhesive if they want a more secure hold. It’s always a good idea to try out different methods on smaller batches before committing to larger-scale candle-making projects.

By securely attaching your wicks to a solid support like a wick bar, you can ensure that they remain in position during the pouring process and prevent them from drifting or moving around. This secures the wick in the center of the candle, allowing for an even burn and preventing tunneling or uneven melting. Take your time to find the method that works best for you and always double-check that your wick is secure before pouring the wax.

In the next section, we will discuss the correct positioning of the wick bar within the candle container for optimal results.

Positioning the Wick Bar in the Candle Container

Once you have prepared the wick bar and secured the wick to it, the next step in candle making is determining the correct positioning of the wick bar within the candle container. Proper placement of the wick bar ensures that the wick remains straight and centered throughout the pouring and cooling process. This section will guide you on how to position the wick bar correctly and provide tips for adjusting its position if needed.

To begin, carefully place the assembled wick bar into your chosen candle container. Ideally, you want to position it in such a way that it stands upright and fits snugly against the sides of the container without touching them. This helps prevent any interference between the burning flame and the container, reducing smoke and other potential hazards. Make sure that there is enough space for wax to flow around and cover all sides of the wick during pouring.

Using a level or measuring tool can help ensure that your wick bar is perfectly vertical within the container. You may also find it helpful to mark or measure where you want your wax level to reach before pouring. Keep in mind that different types of candles may require slightly different positioning depending on their shape or design.

If you find that your wick is not quite centered or straight after placing it with a wick bar, do not worry, as there are ways to adjust its position. Gently shift or angle the wick within its anchoring on the wick bar until it aligns properly with your preferred center point in the container. Take care not to put excessive pressure on either side of your candle during this adjustment process.

By correctly positioning your wick bar within your candle container, you are setting yourself up for success in achieving even burn results once you have poured and cured your candles. The use of a well-aligned, properly placed wick will allow for an optimal burn experience while ensuring consistent performance throughout the candle’s lifespan.

Pouring the Wax

When it comes to candle making, pouring the wax plays a crucial role in achieving an even burn. This section will provide useful tips and techniques to ensure that your candles burn evenly and smoothly, with the help of a wick bar.

Importance of Proper Wax Pouring

Pouring the wax properly is essential for creating high-quality candles. It ensures that the wax surrounds the wick evenly, allowing for an even burn throughout the life of the candle. If the wax is not poured correctly, it can lead to tunneling or uneven burning, where the wick may drown or create excessive soot.

Using a wick bar is especially helpful during this step as it helps maintain the correct position of the wick while you pour the wax. The wick bar secures the wick in place, ensuring that it stays centered and straight during pouring. This consistency helps achieve an even distribution of heat and thorough consumption of wax during burning.

Techniques for Even Wax Pouring

To ensure an even burn for your candles, follow these techniques when pouring the wax:

- Slow and Steady: Pouring too quickly can cause air bubbles or shifts in temperature, leading to uneven burning. Take your time and pour slowly to allow the wax to settle smoothly around the wick.

- Fill in Layers: For larger candles, it is recommended to pour the wax in layers instead of filling up all at once. This technique allows each layer to cool and solidify before adding more wax, preventing uneven sinking or cracking.

- Pause for Cooling: After pouring each layer (if applicable), allow some time for it to cool and partially solidify before proceeding with additional layers. This step further enhances even cooling and minimizes potential cracks or sinkholes.

- Watch Your Pour Temperature: Different types of wax have different ideal pouring temperatures depending on their melting point. Follow the manufacturer’s instructions to ensure you pour the wax at the correct temperature for optimal results.

By following these techniques and utilizing a wick bar, you can achieve consistent and even burning candles. The combination of proper pouring techniques and a well-positioned wick will enhance your candle-making skills, resulting in beautifully crafted candles that burn evenly from start to finish.

Removing the Wick Bar and Trimming the Wick

Once the poured wax has cooled and solidified, it is time to remove the wick bar from the candle and trim the wick to the desired length. This step is crucial for achieving a well-finished and properly burned candle. In this section, we will discuss the process of removing the wick bar without damaging the candle and provide guidance on trimming the wick.

To remove the wick bar, use caution and take your time to ensure that you do not disturb or damage your beautifully poured candle. Gently wiggle and lift the wick bar out of the candle container, making sure not to drag or scrape against any sides of the container.

If you encounter resistance while removing the wick bar, stop immediately and assess if there are any areas where it might be stuck or adhered to excess wax. Applying slight pressure around these areas with a tool like a wooden skewer can help loosen it before attempting removal again.

After successfully removing the wick bar, inspect your candle for any signs of damage or imperfections caused during this process. If there are any minor indentations or irregularities, you can smooth them out gently with a heat gun or by melting excess wax. However, be careful not to overheat or melt too much wax as this may affect how your candle burns.

Now that you have removed the wick bar, it’s time to trim the wick. Trim it down to approximately ¼ inch (6mm) above the surface of the wax. This length will help promote a clean burn with minimal soot and prevent excessive flickering or smoking while lit. Before lighting your newly trimmed candle, double-check its position within the container. Ensure that it is centered and straight by using a ruler or something flat as a guide if necessary.

| Process | Tips |

|---|---|

| Remove the wick bar | – Gently wiggle and lift the wick bar out of the candle container to avoid damage.\n

|

| Trim the wick | – Trim the wick down to approximately ¼ inch (6mm) above the surface of the wax.\n

|

Removing the wick bar and trimming the wick are important final steps in candle making. Taking care during this process will help ensure a well-constructed candle that burns evenly and cleanly. Now that you have completed these steps, your candle is ready for its final curing process before testing its burn quality.

Final Curing and Testing

Once you have completed the candle making process using a wick bar, it is important to allow the candle to cure before testing its burn quality. Curing refers to the process of allowing the candle to fully cool and harden, ensuring that all components have properly set. This step is essential as it ensures that your candle burns evenly and effectively.

To properly cure your candle, it is recommended to allow it to cool for at least 24 hours in a room temperature environment. During this time, resist the urge to touch or disturb the candle as any movements can disrupt its formation and lead to uneven burning.

Once your candle has cured, it is important to test its burn quality before using or selling it. This step helps identify any potential issues before they become larger problems. To conduct a burn quality test, light your candle and observe its performance. Pay close attention to the flame height and shape, as well as any irregularities such as smoking or flickering.

It is also important to note how evenly and cleanly the wax melts around the wick bar. A well-constructed and properly wicked candle should have a consistent melt pool that extends all the way to the edges of the container. If you notice any tunneling or uneven melting, this may indicate an issue with your wick size or pour techniques.

Overall, by properly curing your candle and conducting a burn quality test, you can ensure that your final product meets high standards of excellence. These steps are crucial for enhancing your skills in candle making and creating consistently high-quality candles that customers will love.

| Final Curing and Testing: Checking the Candle’s Burn Quality |

|---|

| – Allow candle to cure for at least 24 hours after pouring |

| – Conduct a burn quality test by lighting the candle and observing its performance |

| – Pay attention to flame height and shape, as well as any irregularities such as smoking or flickering |

| – Ensure a consistent melt pool formation around the wick bar for even burning |

Conclusion

In conclusion, utilizing a wick bar can greatly enhance your candle making skills. Throughout this article, we have explored the importance of using a wick bar for consistent and even burning candles.

By understanding wick sizes and selections for different candle types, preparing the wick bar correctly, securing the wick to the bar, positioning the wick bar within the candle container, pouring the wax properly, and removing the wick bar and trimming the wick, you can ensure high-quality candles with excellent burn quality.

By incorporating the use of a wick bar into your candle making routine, you can achieve consistent and even burns every time. The use of a dedicated tool like a wick bar helps in maintaining the right position for your wicks during pouring and cooling, ensuring that they stay centered for optimal performance. This not only enhances the aesthetic appeal of your finished candles but also prevents any potential safety hazards associated with uneven burns.

We urge all candle makers to give wick bars a try and start adding them to their processes. Taking these extra steps will elevate your candle making skills to new heights and produce high-quality candles that burn evenly from start to finish. Whether you are an experienced chandler or just starting out on your candle-making journey, incorporating a wick bar into your routine will undoubtedly lead to improved results.

In summary, by using a wick bar during every step of the process – from preparation to pouring and finishing touches – you can create consistently beautiful candles that burn evenly and last longer. So don’t hesitate to embrace this tool and enhance your candle making endeavors. With practice and attention to detail, you will become skilled at using a Wick Bar effectively for creating exquisite candles that bring warmth and ambiance into any space.

Frequently Asked Questions

How do you hold a wick in place when making candles?

When making candles, you can hold a wick in place by using various methods. One common way is to use a wick holder or wick bar. These are typically metal or plastic devices that feature a hole where the wick is threaded through. The wick holder is then placed across the top of the container or mold, allowing the wick to stay centered while the wax sets.

Another method involves using simple tools like clothespins or popsicle sticks. The wick can be clamped between these tools and laid horizontally over the top of the container, achieving a similar effect to the wick holder. Ensuring that the wick remains straight and in position during candle-making is crucial for achieving an even burn.

Do you need the metal at the bottom of a candle wick?

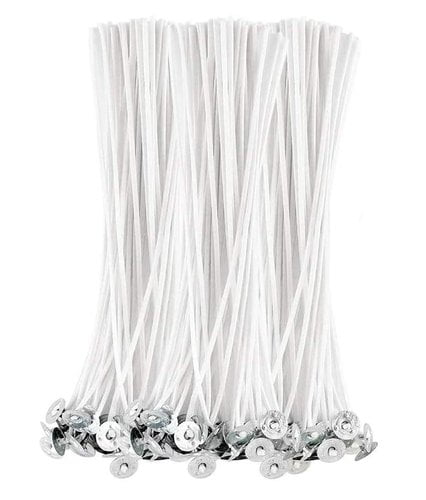

The metal at the bottom of a candle wick, also known as a “wick sustainers” or “wicked bases,” serves an important purpose but isn’t always necessary depending on your specific candle-making process. These metal bases provide stability for the wick and help it stay upright in the center of the candle while it burns.

They also prevent excessive movement and slanting of the flame, resulting in more efficient burning and preventing potential safety hazards such as erratic flames or uneven wax melting. However, if you are making container candles with pre-tabbed wicks (wicks already attached to small metal bases), you may not need additional metal at the bottom of your candle wick.

Do you need wick tabs to make candles?

Wick tabs are typically used when making candles with cotton braided wicks rather than pre-tabbed ones; their usage depends on your preferred candle-making technique. Wick tabs are small metal discs that can be crimped onto the base of a cut-to-length cotton braided wick. This process helps secure and stabilize the wick during pouring and burning since it holds together both ends of the string-like material tightly inside its frame-like structure.

By providing this sturdy attachment point for the wick, the tab ensures that it doesn’t move or shift within the candle as it burns. However, if you are using pre-tabbed wicks or a different type of wick with integrated metal bases, the use of additional wick tabs may not be necessary.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.