Stearic acid is a versatile and commonly used ingredient in the art of candle making. Known for its ability to enhance candle properties, stearic acid offers numerous benefits that can elevate your candle-making experience. In this section, we will delve into the basics of stearic acid, its role in candle making, and the advantages it brings to your homemade candles.

First and foremost, let’s understand what stearic acid actually is. Derived from animal or vegetable fats, stearic acid is a saturated fatty acid that exists in solid form at room temperature. It is widely used across various industries, including cosmetics, food preparation, and of course, candle making.

So why exactly is stearic acid utilized in candle making? The main reason lies in its ability to enhance the performance and appearance of candles. By adding stearic acid to your candle formulation, you can expect an improved burn time and reduced dripping. Additionally, stearic acid also contributes to increasing the hardness and opacity of the wax. This means that your candles will hold their shape better and provide a more consistent burn throughout their lifespan.

The benefits of using stearic acid in candles extend beyond just physical properties. Stearic acid has been found to enhance fragrance throw and improve scent retention in candles. This means that your candles will not only look beautiful but also fill your space with delightful aromas for a longer period of time.

Now that we’ve established what stearic acid is and why it is used in candle making let’s explore the different types and forms available for purchase.

Types and Forms of Stearic Acid for Candle Making

Stearic acid is an essential ingredient in candle making, and understanding the different types and forms available is crucial for achieving the desired results in your candles. Here, we will explore the various options of stearic acid for candle making, guide you on choosing the right form and grade for your candles, and provide information on where to purchase stearic acid.

There are different types of stearic acid available in the market, each with its own characteristics and properties. The two most common forms are vegetable-based stearic acid and animal-based stearic acid.

Vegetable-based stearic acid is derived from plant sources such as palm oil or soybean oil, while animal-based stearic acid is obtained from animal fats. Both types can be used in candle making, but it’s important to consider factors such as sustainability and personal preference when choosing between them.

In addition to the type of stearic acid, you must also consider the grade or quality of the product. Stearic acid comes in various grades, including cosmetic grade, food grade, and industrial grade. For candle making purposes, it is recommended to use commercial/industrial-grade stearic acid as it provides optimal results at a cost-effective price point.

When purchasing stearic acid for candle making, you have several options. Local craft stores often carry a selection of candle-making supplies that include stearic acid. Alternatively, you can find a wide variety of options online through specialty candle-making suppliers or general e-commerce platforms. It’s important to ensure that the supplier you choose provides high-quality products that meet your specific needs.

By carefully considering the type and form of stearic acid you use in your candles and sourcing it from reliable suppliers, you can create candles with exceptional qualities and desired results. Experimentation with different forms and grades can also lead to unique creations that stand out among others. So make sure to explore the options available and find the stearic acid that perfectly suits your candle-making needs.

Safety Precautions and Handling of Stearic Acid

Stearic acid is a commonly used ingredient in candle making, but it is important to take proper safety precautions when handling this substance. This section will outline the necessary steps for safely storing and working with stearic acid.

First and foremost, it is crucial to store stearic acid in a cool, dry place away from direct sunlight. This will help prevent any degradation or changes in its chemical composition. Additionally, keep stearic acid away from sources of ignition such as open flames or sparks, as it is flammable.

When working with stearic acid, it is essential to follow appropriate safety measures. Always wear protective equipment such as gloves and goggles to protect yourself from potential harm. In case of accidental skin contact, immediately wash the affected area with soap and water. If stearic acid comes into contact with your eyes, rinse them thoroughly with water for at least 15 minutes and seek medical attention if necessary.

Furthermore, ensure that you are working in a well-ventilated area when using stearic acid. Adequate ventilation helps minimize exposure to fumes and reduces the risk of respiratory irritation. If ventilation is limited, consider wearing a mask or using a fume hood to protect your lungs.

| Safety Precautions | Handling Tips |

|---|---|

| Store stearic acid in a cool, dry place away from direct sunlight | Follow appropriate safety measures such as wearing gloves and goggles |

| Avoid sources of ignition like open flames or sparks | In case of accidental skin contact, wash the affected area with soap and water immediately |

| Work in a well-ventilated area or use a mask/fume hood if ventilation is limited | Rinse eyes with water for at least 15 minutes if stearic acid comes into contact with them |

How to Incorporate Stearic Acid in Candle Formulation

One of the key steps in candle making is properly incorporating stearic acid into your candle formulation. Stearic acid is commonly used in candle making due to its ability to enhance hardness, texture, and burn time. Here is a step-by-step guide on how to incorporate stearic acid into your candle formulation:

Step 1: Measuring and calculating the right amount of stearic acid

Before you begin incorporating stearic acid into your candle formulation, it’s important to determine the right amount needed for your specific recipe. The recommended usage rate for stearic acid in candles is typically between 3% to 10%, depending on the desired outcome.

To calculate the amount of stearic acid needed, multiply the total weight of your wax by the desired percentage (in decimal form). For example, if you are using 1 pound (16 ounces) of wax and want a 6% concentration of stearic acid, you would multiply 16 by 0.06 to get 0.96 ounces of stearic acid.

Step 2: Melting and mixing techniques for optimal dispersion

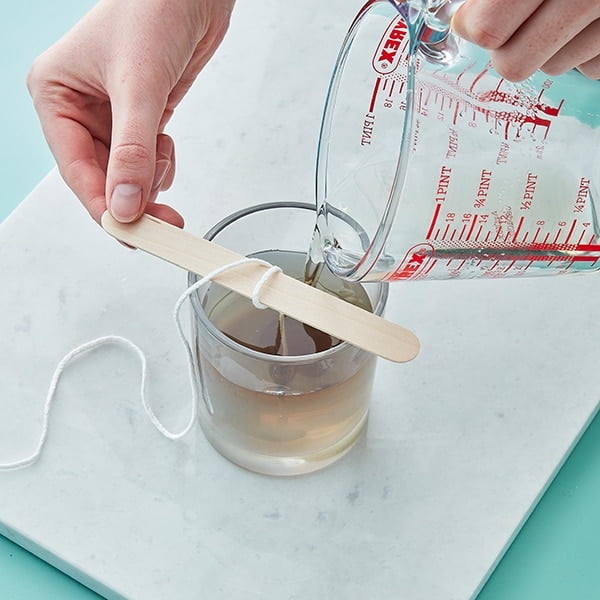

To incorporate the stearic acid into your candle formulation, start by melting your wax as usual. Once the wax has reached its melting point, it’s time to add the measured amount of stearic acid. Sprinkle the powdered or flaked form of stearic acid evenly over the surface area of melted wax while stirring continuously. This will ensure proper dispersion and prevent clumping or uneven distribution.

Step 3: Mixing techniques for optimal dispersion

After adding the stearic acid to the melted wax, continue stirring gently but consistently until all solid particles have dissolved completely and become fully incorporated with the wax. Ensure that there are no visible lumps or granules left behind before pouring your wax into the container or molds. It’s important to note that stearic acid has a higher melting point than most waxes, so make sure to mix thoroughly and avoid overheating the mixture.

By following these steps, you can effectively incorporate stearic acid into your candle formulation, maximizing its benefits and achieving the desired candle properties. Remember to always experiment and adjust the amount of stearic acid based on your specific preferences and desired outcomes.

Effects of Stearic Acid on Candle Properties

Stearic acid plays a significant role in determining the properties of candles. When used in candle making, stearic acid can have a substantial impact on candle hardness, texture, and burn time. By understanding how to properly incorporate stearic acid, candle makers can achieve desired results and create high-quality candles.

One of the primary effects of stearic acid in candles is the enhancement of hardness. Stearic acid has the ability to increase the melting point of wax, resulting in a harder and more durable candle. This makes it especially useful when making pillar or votive candles that require a solid structure. By incorporating stearic acid into the formulation, candle makers can create candles that are less prone to bending or warping.

In addition to hardness, stearic acid also affects the texture of candles. It has been found that stearic acid can provide a smooth and creamy texture to candle wax when used correctly. This contributes to an overall pleasing aesthetic for the finished product.

Moreover, stearic acid can influence the burn time of candles. By adding stearic acid to the wax formula, candle makers can extend the burn time of their creations. This is particularly beneficial for customers who value long-lasting candles as they will be able to enjoy their favorite scents for a longer period.

To achieve these desired effects on candle properties with stearic acid, it is important to adjust its concentration accordingly. However, it is worth noting that increasing the level beyond recommended limits may result in negative outcomes such as reduced scent throw or potential issues with frosting.

| Candle Properties | Effects |

|---|---|

| Hardness | Increased hardness and durability |

| Texture | Smooth and creamy texture |

| Burn Time | Extended burn time |

Troubleshooting Common Issues with Stearic Acid in Candle Making

Dealing with Frosting, Tunneling, or Cracking

One common issue that candle makers may encounter when using stearic acid is frosting, tunneling, or cracking in their candles. Frosting refers to the crystalline appearance that can occur on the surface of the candle, while tunneling and cracking refer to uneven burning patterns and fractures in the wax, respectively. These issues can be frustrating for candle makers, but there are ways to prevent and address them.

To minimize frosting, it is important to properly cool your candles. Rapid temperature changes can contribute to frosting, so ensure that your candles cool down slowly and evenly. Placing them in a cool room without drafts or sudden temperature changes can help reduce the risk of frost formation.

Tunneling can be prevented by ensuring that the wick is properly centered and trimmed. A well-centered wick will burn more evenly and reduce the chances of tunneling. Additionally, allowing your candles to burn for long enough during each use will help to melt the entire top layer of wax evenly, preventing tunnelling from occurring.

Cracking may happen if there is too much stearic acid in your candle formula. Stearic acid can make the wax harder and more brittle when used in excessive amounts. To avoid cracking, it is crucial to measure and calculate the appropriate amount of stearic acid for your specific candle formulation.

Identifying and Fixing Issues Related to Stearic Acid Usage

If you encounter issues related specifically to stearic acid usage in your candle making process, it is important to identify the root cause in order to find an appropriate solution.

One potential problem could be insufficient mixing of stearic acid into the wax. Improper dispersion of stearic acid may result in uneven distribution throughout the candle, leading to inconsistent burning properties. To fix this issue, consider using a double boiler or heating your wax to a higher temperature, which can aid in better incorporation of stearic acid.

Another issue could be related to the type or grade of stearic acid you are using. Different types and grades of stearic acid have varying melting points, purity levels, and chemical compositions, which can affect their performance in candle making. Experimenting with different forms and grades may help you determine which works best for your specific needs.

Remember that it is important to keep track of any changes you make during troubleshooting. By documenting your adjustments and their outcomes, you can learn from the process and refine your future candle making endeavors.

Tips and Tricks for Overcoming Challenges when Using Stearic Acid

When facing challenges related to using stearic acid in candle making, there are several tips and tricks that can help overcome these obstacles.

One tip is to conduct small-scale test batches before producing larger quantities of candles. This allows you to observe how your candles perform with varying levels of stearic acid and make necessary adjustments accordingly. Testing different concentrations of stearic acid will also enable you to find the optimal amount that achieves the desired properties for your candles.

Additionally, considering the combination of other additives with stearic acid can enhance its effects and address certain issues. For example, using a vybar additive along with stearic acid can help reduce frosting and improve fragrance retention in candles. Exploring different combinations of additives can provide unique solutions for your candle making challenges.

Finally, reaching out to experienced candle makers or joining online communities dedicated to candle making can be valuable sources of advice and support when encountering difficulties with stearic acid usage. Learning from others’ experiences and sharing knowledge within these communities can contribute to successful troubleshooting efforts.

By following these tips and tricks, candle makers can navigate through challenges associated with using stearic acid in candle making while achieving high-quality results in their finished products.

Combining Stearic Acid with Other Additives for Unique Candle Creations

Stearic acid is a versatile ingredient in candle making that can be combined with other additives to create unique and beautiful candles. By experimenting with different additives, candle makers can enhance the visual appeal and scent of their creations. Here are some techniques and ideas for combining stearic acid with other additives for unique candle creations.

Exploring different additives that can be combined with stearic acid

There are various additives that can be combined with stearic acid to achieve different effects in candles. One popular additive is vybar, which is a polymer that helps to improve the opacity and color vibrancy of the wax. By adding vybar to the stearic acid mixture, candle makers can create candles with more vibrant colors and better opacity.

Another additive that works well when combined with stearic acid is microcrystalline wax. Microcrystalline wax has a high melting point and helps to increase the hardness of the candle. When mixed with stearic acid, it can create a more durable and longer-lasting candle.

Techniques for incorporating stearic acid in colored or scented candles

When creating colored or scented candles, it’s important to consider how the addition of stearic acid may affect these aspects. To incorporate stearic acid into colored candles, it is recommended to add colorants before adding the stearic acid mixture. This ensures that the color stays vibrant and evenly dispersed throughout the wax.

For scented candles, fragrance oils should typically be added after incorporating the stearic acid mixture into the wax. This allows for optimal dispersion of both fragrance and stearic acid throughout the candle, resulting in a consistent aroma.

Experimenting with stearic acid to create special effects and designs

Stearic acid offers endless possibilities for creating special effects and designs in candles. One way to achieve unique effects is by using stearic acid in layered or swirled candles. By adding different concentrations of stearic acid to each layer, candle makers can create beautiful patterns and designs.

Another technique is to use stearic acid as a mold release agent. This involves applying a thin layer of melted stearic acid to the inside of a mold before pouring the wax. The stearic acid creates a barrier between the wax and the mold, making it easier to remove the finished candle without damaging its shape.

Cleaning and Maintenance of Equipment Used with Stearic Acid

Properly cleaning and maintaining the equipment used in stearic acid candle making is crucial for ensuring the longevity of your tools and utensils. Regular maintenance not only prevents contamination but also helps to avoid cross-contamination risks when working with stearic acid. Here are some essential steps to follow for cleaning and maintaining your equipment.

First, it is important to note that stearic acid can be difficult to remove once it hardens on surfaces. Therefore, it is recommended to clean your equipment immediately after use, before the stearic acid has a chance to solidify. We recommend using hot water and dish soap for initial cleaning. This will help dissolve any residual stearic acid and make it easier to remove.

For stubborn residue or hardened stearic acid, it may be necessary to use a solvent or specialized cleaner specifically designed for wax removal. Follow the instructions provided by the manufacturer of the cleaner and ensure proper ventilation when using solvents.

In addition to regular cleaning, proper maintenance of your equipment is essential. This includes storing utensils and tools in a clean, dry place when not in use, protecting them from dust and other contaminants. It is also important to inspect your equipment periodically for any signs of wear or damage. Replace any worn-out or damaged tools promptly to avoid compromising the quality of your candles.

By following these cleaning and maintenance practices, you can ensure that your equipment remains in good condition for future candle making projects. Taking care of your tools will not only save you time and money but also contribute to consistently producing high-quality candles infused with stearic acid.

In conclusion, while working with stearic acid in candle making brings its own set of challenges, properly cleaning and maintaining the equipment used can make a significant difference in the success of your candle-making endeavors. By following these guidelines, you can prevent contamination risks and keep your equipment in top shape. With the right care and attention, you can continue to create beautiful candles with the benefits that stearic acid provides.

Frequently Asked Questions

How do you use stearic acid for candle wax?

Stearic acid is commonly used in candle making as an additive to improve the hardness and opacity of the wax. To use stearic acid for candle wax, you can either add it directly to the melted wax or pre-blend it with the fragrance oil before adding it to the wax.

When adding stearic acid directly to the melted wax, it is essential to heat the stearic acid separately and then slowly pour it into the melted wax while stirring continuously until fully incorporated. This ensures that the stearic acid disperses evenly throughout the wax, resulting in a more consistent candle.

How do you add stearic acid to soy wax candles?

Adding stearic acid to soy wax candles can enhance their performance by increasing hardness, improving burn time, and reducing sooting. When working with soy wax, it is recommended to add stearic acid at around 3-5% of the total weight of the wax. To incorporate stearic acid into soy wax candles, measure out the desired amount of stearic acid and melt it separately from the soy wax.

Once both are melted, combine them together while stirring constantly until well blended. It’s important not to overheat or exceed recommended temperatures when melting or combining these ingredients as it may affect the overall quality of your candles.

Do you need stearic acid in candles?

The use of stearic acid in candles is not mandatory; however, it does offer several advantages that many candle makers find beneficial. Stearic acid helps to increase a candle’s melting point, making them less prone to softening or melting in warmer conditions. It also improves opacity for better color vibrancy and makes candles harder, preventing them from becoming too soft or easily deformed.

Additionally, stearic acid aids in reducing sooting and dripping during burning by providing more structure and stability to the candle flame. Ultimately, whether or not you need to use stearic acid in your candles depends on your desired outcome and specific preferences for the final product.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.