Pillar candles are a popular choice for home décor and gifts due to their classic shape and versatility. Whether you are a hobbyist or a professional candle maker, investing in a pillar candle making machine can significantly streamline the production process. These machines are designed to efficiently create beautiful pillar candles of various sizes, shapes, and colors.

The art of pillar candle making dates back centuries, with evidence of their use in ancient civilizations for religious ceremonies and lighting. Over time, pillar candles have evolved into a staple in modern home décor, adding ambiance and warmth to any space. With the advancement of technology, the introduction of pillar candle making machines has revolutionized the industry by simplifying the manufacturing process.

Using a pillar candle making machine offers numerous benefits, including increased productivity, consistency in candle quality, and cost-effectiveness in large-scale production. These machines come in different types to cater to various needs and preferences, ranging from manual to fully automatic models.

In the following sections, we will explore the history of pillar candles, the benefits of using a machine, step-by-step guides on how to use them, tips for selecting the right machine, maintenance instructions, creative design ideas, and ultimately embracing the art of pillar candle making with these innovative devices.

History of Pillar Candles

Pillar candles have a rich history that dates back centuries, with their origins traced to ancient Egypt and Rome. In these early civilizations, pillar candles were primarily used for religious or ceremonial purposes. The cylindrical shape of the pillar candle symbolized strength and stability, making it a popular choice for rituals and ceremonies.

Evolution of Pillar Candles

Over time, the use of pillar candles evolved beyond religious practices and became a staple in households for decorative and functional purposes. During the Middle Ages, beeswax became a popular material for making pillar candles due to its clean-burning properties. The development of different waxes and fragrance options further enhanced the appeal of pillar candles as they gained popularity as decorative items.

Influence on Modern Candle Making

As candle making techniques advanced during the Industrial Revolution, the production of pillar candles became more streamlined and efficient. The invention of the pillar candle making machine revolutionized the industry by allowing mass production of these candles.

This technological innovation made pillar candles more accessible to consumers worldwide, leading to their widespread use in homes, restaurants, hotels, and other establishments. Today, pillar candle making machines continue to play a vital role in meeting the demand for these versatile and elegant candles.

Benefits of Using a Pillar Candle Making Machine

Pillar candles are a popular choice for home décor, aromatherapy, and special occasions. However, creating these candles can be a time-consuming and labor-intensive process if done manually. This is where a pillar candle making machine comes in handy. These machines offer numerous benefits that make the candle-making process more efficient and enjoyable.

One of the key benefits of using a pillar candle making machine is the time-saving aspect. Instead of manually pouring wax into molds and waiting for it to set, a machine can automate this process with precision and speed. This not only saves time but also allows for higher production volumes, making it ideal for businesses or individuals looking to create pillar candles in bulk.

Furthermore, a pillar candle making machine ensures consistency in the quality of the candles produced. By controlling factors such as temperature, pouring speed, and cooling time, these machines can create uniform pillars with smooth surfaces and even burning characteristics. This level of consistency is crucial for those who want to sell their candles or gift them to others as it enhances the overall aesthetic appeal and performance of the final product.

| Benefits | Description |

|---|---|

| Time-saving | Pillar candle making machines automate the process, saving time and allowing for higher production volumes |

| Consistent Quality | These machines ensure uniform pillars with smooth surfaces and even burning characteristics, enhancing aesthetic appeal |

Types of Pillar Candle Making Machines

When it comes to creating pillar candles, having the right equipment is essential. Pillar candle making machines come in various types, each designed for specific purposes and production capacities. One common type is the semi-automatic pillar candle making machine, which strikes a balance between manual labor and automation. This type of machine is ideal for small to medium-scale production, offering efficiency while still allowing for hands-on control over the candle-making process.

Another popular type of pillar candle making machine is the fully automatic version. This machine is suitable for large-scale production and is capable of producing a high volume of pillar candles in a shorter amount of time. Fully automatic machines are equipped with advanced features such as programmable settings and precise temperature control, ensuring consistency in the quality of the candles being produced. These machines are often used by commercial candle manufacturers who prioritize efficiency and productivity.

In addition to semi-automatic and fully automatic machines, there are also custom-designed pillar candle making machines that can be tailored to meet specific production requirements. These customized machines are perfect for businesses with unique needs or specialized candle designs. By working closely with manufacturers to create a bespoke pillar candle making machine, companies can optimize their production processes and achieve their desired outcomes efficiently.

| Pillar Candle Making Machine Type | Production Capacity |

|---|---|

| Semi-Automatic | Small to Medium-scale |

| Fully Automatic | Large-scale |

| Custom-Designed | Tailored to Specific Needs |

Step-by-Step Guide to Using a Pillar Candle Making Machine

Pillar candles have always been a popular choice for home decor, gifts, and special occasions. Making pillar candles by hand can be a time-consuming process, which is why many candle makers are turning to pillar candle making machines to streamline their production. These machines offer efficiency and consistency in creating beautiful pillar candles, making the candle-making process much easier and faster.

When using a pillar candle making machine, it’s essential to follow the proper steps to ensure successful candle production. Here is a step-by-step guide to using a pillar candle making machine:

- Prepare your work area: Set up your pillar candle making machine on a flat, stable surface with easy access to power outlets and necessary supplies.

- Choose your wax: Select the type of wax you want to use for your pillar candles. Paraffin wax is commonly used for its ease of use and ability to hold color and fragrance well.

- Melt the wax: Place chunks of wax into the melting pot of the machine and heat it until it reaches the desired temperature for pouring into molds.

- Add color and fragrance: Once the wax is melted, stir in any color dyes or fragrance oils you want to incorporate into your candles.

- Pour into molds: Carefully pour the melted wax into your chosen molds within the machine, ensuring an even distribution.

- Allow cooling time: Let the candles cool and harden within the molds before removing them from the machine for further curing.

By following these steps, you can effectively utilize a pillar candle making machine to create stunning candles with ease. The convenience of these machines allows both novice and experienced candle makers to produce high-quality pillar candles efficiently. Whether crafting for personal enjoyment or starting a small business venture, a pillar candle making machine can be a valuable tool in enhancing your candle-making skills.

Tips for Choosing the Right Pillar Candle Making Machine

When it comes to choosing the right pillar candle making machine, there are several factors to consider in order to ensure a successful and efficient candle-making process.

Capacity and Output

One of the key factors to consider when selecting a pillar candle making machine is its capacity and output capabilities. Different machines come in varying sizes and can produce different quantities of candles per batch. Depending on your production needs, it is important to choose a machine that can accommodate the volume of candles you intend to produce.

Features and Functions

Another important aspect to consider is the features and functions of the machine. Some machines offer more advanced capabilities such as temperature control, automatic pouring, or customizable molds. Depending on your level of experience and desired outcomes, you may want to opt for a machine with these additional features to enhance your candle-making process.

Budget and Cost

Budget considerations are also crucial when choosing a pillar candle making machine. The cost of these machines can vary depending on their size, capacity, features, and brand.

It is important to set a budget and compare different options within that range to find a machine that meets your needs without exceeding your financial constraints. With careful consideration of capacity, features, and budget constraints, you can select the right pillar candle making machine that will help you create beautiful candles efficiently and effectively.

Maintenance and Care for Pillar Candle Making Machines

Pillar candle making machines are essential tools for efficiently creating beautiful and intricate pillar candles. To ensure that your machine continues to function effectively and has a long lifespan, proper maintenance and care are crucial. Here are some tips on how to keep your pillar candle making machine in top condition:

- Regular Cleaning: It is important to clean your pillar candle making machine after each use to prevent wax build-up and ensure smooth operation. Use a soft cloth or brush to remove any residue from the machine’s components.

- Lubrication of Moving Parts: To maintain optimal performance, lubricate the moving parts of the machine regularly. This will help reduce friction and wear, extending the life of your pillar candle making machine.

- Inspecting for Wear and Tear: Periodically check your machine for any signs of wear or damage, such as frayed wires or loose components. Addressing these issues promptly can prevent further damage and potential safety hazards.

Proper storage is also important when it comes to maintaining your pillar candle making machine. Store it in a dry and cool place away from direct sunlight to prevent damage from exposure to heat or moisture. Additionally, follow the manufacturer’s guidelines for storage to ensure that your machine remains in good working condition for years to come.

Taking care of your pillar candle making machine not only prolongs its lifespan but also ensures that you can continue creating stunning candles with ease. By incorporating regular maintenance into your candle-making routine, you can enjoy the benefits of using a pillar candle making machine for many projects to come.

Creative Ideas for Pillar Candle Designs

Pillar candles have long been a popular choice for home décor, as they provide a classic and elegant touch to any space. With the help of a pillar candle making machine, enthusiasts can take their creativity to new heights by producing unique and beautiful designs.

One creative idea for pillar candle designs is incorporating different colors and scents into the candles. By using the right tools and techniques with a pillar candle making machine, crafters can create multicolored or layered candles that not only look visually stunning but also fill the room with delightful fragrances.

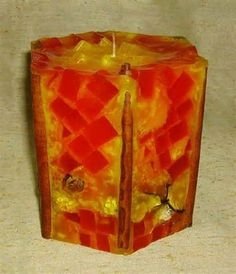

Another innovative design idea for pillar candles is embedding decorative elements into the wax. This can include dried flowers, herbs, spices, or even glitter to add a touch of glamour to the candles.

Using a pillar candle making machine allows for precise control over the pouring and setting process, ensuring that these elements are evenly distributed throughout the candle. Crafters can experiment with different combinations of embeds to create one-of-a-kind designs that reflect their personal style and creativity.

For those looking to add a touch of whimsy or nostalgia to their pillar candles, custom molds are an excellent option. With a variety of shapes and sizes available for use with pillar candle making machines, crafters can create themed candles for special occasions or holidays.

From geometric patterns to intricate sculptures, the possibilities are endless when it comes to designing unique pillar candles with the help of a machine. By exploring different molding techniques and experimenting with various materials, enthusiasts can unleash their imaginations and produce truly memorable pieces that will impress friends and family alike.

Conclusion

In conclusion, the art of pillar candle making has been revolutionized with the introduction of pillar candle making machines. These innovative tools have made the process of creating beautiful and intricate pillar candles more accessible to both beginners and experienced crafters alike. By automating certain steps and increasing efficiency, these machines have enabled enthusiasts to explore their creativity and express themselves through unique candle designs.

One of the key advantages of using a pillar candle making machine is the time saved in producing batches of candles. With the ability to automate pouring, cooling, and shaping processes, crafters can focus on experimenting with different colors, scents, and shapes without being bogged down by tedious manual tasks. This efficiency allows for greater productivity and opens up possibilities for exploring new techniques in candle making.

Furthermore, maintaining a pillar candle making machine is crucial to ensure its longevity and optimal performance. By regularly cleaning and lubricating the machine, as well as following manufacturer guidelines for usage, crafters can enjoy many years of creativity and inspiration. Embracing the art of pillar candle making with a machine not only provides a fulfilling creative outlet but also offers a practical way to enhance one’s living space with handmade candles that reflect individual style and personality.

Frequently Asked Questions

What Do You Need to Make Pillar Candles?

To make pillar candles, you will need supplies such as wax, wicks, a double boiler or melting pot, a thermometer, fragrance oils (if desired), colorants (if desired), molds, and a stirring utensil. It’s important to follow safety precautions when working with hot wax.

What Is the Cost of Manual Candle Making Machine?

The cost of a manual candle making machine can vary depending on the brand, size, and features it offers. On average, a manual candle making machine can range from $50 to $200 or more. It is essential to consider your budget and needs before making a purchase.

What Is the Best Wax for Pillar Scented Candles?

The best wax for pillar scented candles is typically paraffin wax or a blend of paraffin and soy wax. Paraffin wax is known for its ability to hold fragrance well and produce vibrant colors.

Soy wax can also be used for a more natural option that still offers good scent throw in pillar candles. Ultimately, the best wax choice depends on personal preference and the specific qualities you are looking for in your candles.

Welcome to my candle making blog! In this blog, I will be sharing my tips and tricks for making candles. I will also be sharing some of my favorite recipes.